Wearable sensors that can perform motion detection and health monitoring play an important role in our daily life. But most of the sensors are soft and cannot protect the human body. In order to solve this problem, researchers at the University of Southern California found a way to learn from nature and use 3D printing to fabricate bioinspired smart structures.

The answers lie in the lightweight and strong structure found in natural nacre. After tens of thousands of years of evolution, hierarchical structures in nacre led to superior mechanical performances from its “brick and mortar” structures to effectively protect the soft body.

In nacre’s “brick and mortar” (BM) architecture, the CaCo3 platelets act as the brick, and the chitin and protein fibers act as mortar. These hierarchically ordered structures range from nano/microscopic to form macroscopic nacre structures. The structures generate crack deflection and absorb the energy during impact, thus enhancing the toughness of natural nacre. These outstanding properties represent a source of inspiration for designing lightweight and strong armor to protect the human body. We used engineered material-graphene nanoplatelets to replace the CaCO3 platelet in nature. The graphene nanoplatelets possess both excellent mechanical and electrical properties.

The traditional process to fabricate nacre-inspired structure is focused on the 2D thin film fabrication or simple shape bulk structures. But the thin film or bulk structures are not enough for practical applications. 3D printing gives us a new way to fabricate controllable 3D shapes that will have a wider application.

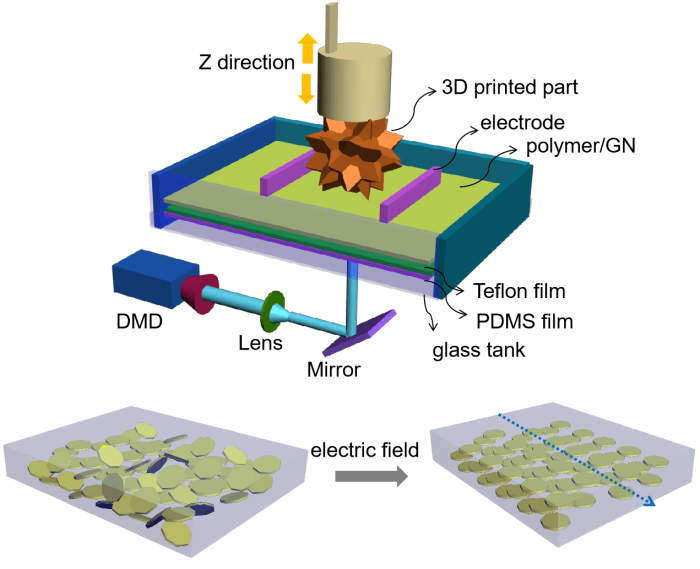

The research led by Prof. Yong Chen from USC is focused on the 3D printing of bioinspired lightweight smart structures. Researchers used the electric field to align the graphene nanoplatelets (GN) in the photocurable resin from Maker-juice (MJ) during the 3D printing process, and the 3D structure was fabricated layer by layer. Graphene nanoplatelets were first surface modified to enhance the bonding and load transfer with polymer chains.

The proposed fabrication procedure takes advantages of the nano-scale to micro-scale assembly induced by the electric field and the micro-scale to macro-scale assembly by 3D printing. The 3D printed nacre with aligned GN shows “brick and mortar” structures similar to microstructures with natural nacre, where the GN act as brick and photocurable polymer in between act as mortar (Figure). The researchers found that the 3D printed artificial nacre with aligned GN shows comparable specific toughness and strength with natural nacre. In addition, it has an anisotropic electrical property that natural nacre does not have.

Figure courtesy Yang Yang.

A 3D printed piezoresistive smart helmet with nacre-inspired microstructures was fabricated. The smart helmet shows a high toughness with protective property and self-sensing capability to detect the crack by detecting the resistance change. The LED light stays on in the initial state. When a crack occurs in the helmet, the light intensity decreases and acts as an alarm that a crack is in the helmet. This helps us to detect the crack at the early stage and will enhance the safety of the helmet. The electrically assisted 3D printing method gives us a new way to fabricate bioinspired hierarchical structures with reinforced mechanical and electrical properties.