Bread is a typical staple food of the human diet whose consumption is rapidly growing. Whole wheat bread is gaining popularity since it contains a good amount of health-beneficial fiber and minerals. Moreover, the bread contains a low amount of fat, cholesterol, and essential amino acids (lysine). Essential amino acids, the building blocks of protein, are not manufactured in our body, and thus need to be taken from food rich in essential amino acids, such as pulses.

Functional bread has the potential to provide health benefits to humans beyond essential nutrients. In the past, functional whole wheat bread was reported to lower the chances of coronary heart disease, gastrointestinal pathologies, a few forms of cancer, and type 2 diabetes, in addition to its nutritional benefits (Gonzalez-Anton, Artacho, Ruiz-Lopez, Gil, & Mesa, 2017; Mikušová et al., 2013). Legume powder can be a good protein supplement for carbohydrate-rich cereal-based products such as bread. Cryogenic grinding, a low-temperature grinding technique, is preferred over the conventional method for obtaining high-quality cereal, pulses, and spice powders.

Although pulses such as green gram (Phaseolus aureus Roxb.) are rich in proteins, minerals, and bio-accessible total polyphenols, they contain certain antinutrients. In general, antinutrients, for example, phytate, tannins, and trypsin inhabitors reduce nutrient utilization/absorption in the human body. Therefore, fermentation and/or germination of pulses have been suggested/reported in the literature to expel these antinutrients. Fermentation of green gram flour helps in increasing the digestibility of soluble proteins, proteins, in vitro protein, and free amino acids. Thus, fermented green gram flour can be supplemented to wheat flour when making functional bread.

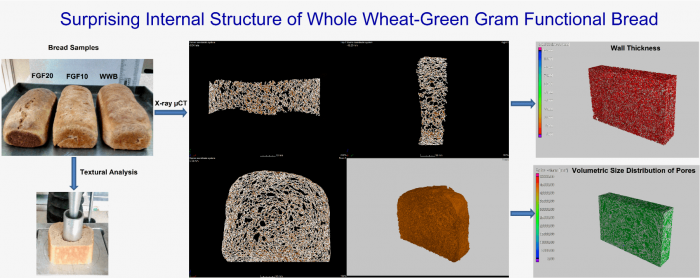

In the past, attempts were made by different researchers to develop functional bread. However, the interesting relationships between microstructure/micro-properties and macro-properties of bread were not presented. Recently, a team of Indian researchers has used x-ray micro-computed tomography (x-ray µCT) for analysis of the internal structure of whole wheat-green gram functional bread. Furthermore, the researchers presented the effect of microstructural characteristics on macro-properties such as crumb hardness and specific loaf volume of bread.

An AACC straight-dough method 10-10.03 was used for the formulation of bread. Whole wheat flour was partially replaced by cryo-ground fermented green gram flour (10% and 20%). Green gram flour was fermented using a solid-state fermentation technique which was ground under cryogenic conditions to obtain an innovative ingredient, i.e., cryo-ground fermented flour. The x-ray µCT technique, coupled with image analysis, was utilized to study microstructural aspects of bread: (a) standard whole wheat bread (WWB); and (b) two functional breads having 10% and 20% of cryo-ground fermented flour called FGF10 and FGF20, respectively. A 20 mm thick slice from the central region of the bread loaf was taken for scanning/experimentations.

Fig. 1. Graphical abstract of the study. Figure courtesy Bhupendra M Ghodki

Results showed the amazing internal architecture of WWB, FGF10, and FGF10 bread; for example, the internal structure of WWB is shown in Fig. 1 (graphical abstract of the study). Further, a significant variation can be observed in the microstructure, i.e., the spatial organization of elements such as open-pore, closed-pore, and cell/pore wall material, along with their mutual interaction. The open pores are cells that are spatially connected to the adjacent cells, while closed pores are not connected with neighboring cells. In all the samples, the highest volume was occupied by a single open pore compared to closed pores.

Among the three samples, WWB possessed the highest height of loaf, i.e., WWB: 56.98 mm > FGF10: 53.43 mm > FGF20: 46.69 mm. Moreover, the crumb characteristics, for example, the total number of pores, interconnectivity index, total volume, total surface area of pores, porosity, sphericity of closed pores, the diameter of open pores, and uniform volumetric size distribution of pores followed the similar trend. It is interesting to note that the specific loaf volume, a macro-property, also displayed an analogous trend, i.e., WWB > FGF10 > FGF20. On the contrary, FGF 20 recorded the maximal values for cell/pore wall thickness, volume fraction of solid phase, volume fraction of major wall in the solid phase, sphericity of open pores, percentage of closed pores, diameter of closed pores, and volume of closed pores, which was followed by FGF10 and WWB, respectively. Accordingly, crumb hardness was also reported to follow the following trend: WWB < FGF10 < FGF20.

Overall, the x-ray µCT technique coupled with image analysis offered a better understanding of the compelling internal structure/architecture of standard and functional breads. Further, the results provided an important insight into the microstructural properties of bread samples involving cell wall material and pore properties along with their interaction with textural properties.