Electrical energy storage technologies are an important solution for a mismatched problem between the distributed intermittent power generation (like solar and wind power) and stabilization of the local grid electricity supply.

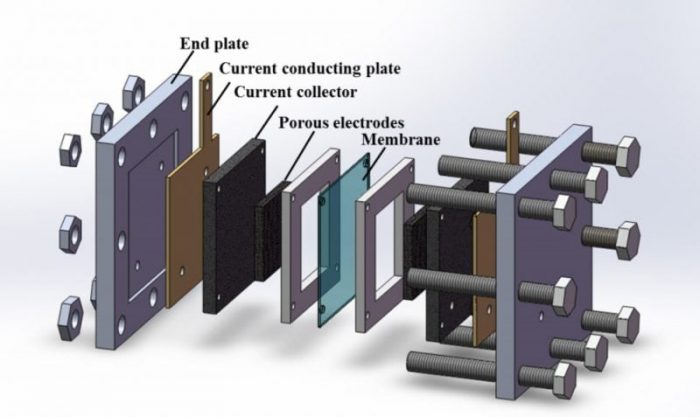

Among various energy storage techniques, the vanadium redox flow battery (VRFB) is a prospective energy storage technique with potential, because of the technique’s advantages, such as flexible power rating design and long life cycle. VRFB stores energy in vanadium-based electrolytes (shown in Fig. 1), and the electrolytes are circulated by two pumps from the two reservoirs to each half cell.

Fig. 1 Schematic of the component of a VRFB. (Image credit: Z.G. Qu)

To reduce the contact resistance between the battery components, all the components of the battery are clamped together during assembly. The electrode is non-uniformly compressed in the cell with flow fields because of the contacted rib-channel patterns on the current collector. The influences of a non-uniformly compressed electrode on the VRFB performance is quantitatively evaluated.

The morphological variation (intrusion ratio and porosity), the mechanical property (strain–stress), electrical characteristics (area specific resistance), hydraulic characteristic (pressure drop), and charge/discharge performance (energy efficiency) of VRFB with a serpentine flow field and compressed electrodes are systematically characterized under different electrode compression ratios (CRs).

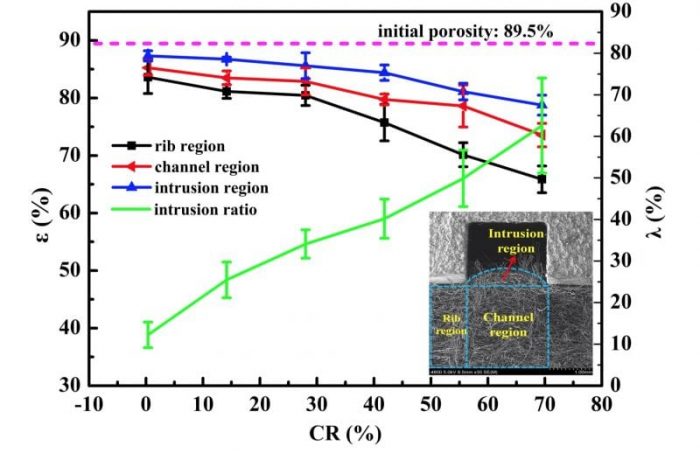

In the morphological deformation measurement, the intrusion ratio (λ) is obtained by adopting the binary image analysis from the SEM photo (shown in Figure 2 (a)). The electrode intrusion fraction increases linearly with the CR (shown in Fig. 2 (b)). According to different deformation degrees from the obtained SEM, the electrode is treated as three parts: the fully compressed rib region, the less compressed channel region, and the minimally compressed intrusion region.

The average local electrode porosities (shown in Fig. 2(c)) of those three parts are detected based on the SEM photo. The porosities of those parts decrease with CR, and the electrode porosity in the rib region shows a significant decrease, while that of the intrusion region is the mildest. The electrode contact resistance is reduced and the flow resistance is improved for the compressed electrode. A maximum of 19.4% improvement in energy efficiency can be obtained when the CR is 41.8%, and then is followed by a decrease with a further increase in CR. What’s more, the measured local porosities and geometric deformation parameters are then used in modeling the VRFB with flow field and the non-uniformly compressed electrode.

The results showed that the bulk velocity species and mass transfer is improved in the non-uniformly compressed electrodes. An optimized electrode CR was found, which exhibits the maximum concentration uniformity and minimum overpotential. The consideration of morphological variations including intrusion part in the flow channel and non-uniformly distributed porosity can guide the VRFB design when the compressed electrode is considered.

Fig. 2 The characteristics of the morphological variation of the compressed electrode with respect to CRs. (Image credit: Z.G. Qu)

These findings are described in the article Experimental study on the performance of a vanadium redox flow battery with non-uniformly compressed carbon felt electrode, recently published in the journal Applied Energy. This work was conducted by Dr. Q. Wang, Prof. Z.G. Qu, Dr. Z.Y. Jiang, and Prof. W.W. Yang from Xi’an Jiaotong University.