Every year, the global consumption of raw materials increases. In the 19th century, only a few elements were extracted and used. Today the whole periodic table is practically used by society, and many of the considered “critical” or “rare” elements are used in green technologies.

Such technologies shall be the best answer to reduce carbon emissions and achieve the 2ºC limit of temperature increase, as agreed by the United Nations in the conference of the parties in Paris (COP 21). This situation is going to imply a drastic change in the energy sector, increasing the installed power of wind and solar technologies, as well as shifting from conventional to electric vehicles in the mobility sector. Yet this transition must be carefully accomplished as huge amounts of raw materials are going to be required, increasing the pressure on raw material availability.

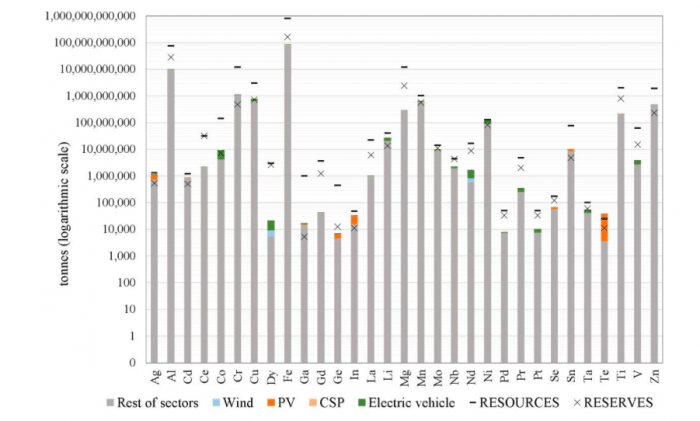

Using a bottom-up and top-down approach, data regarding raw material needs for each green technology (from 2016 to 2050) have been compared with global reserve and resources data for each different element, as extraction is ultimately limited by the amount of minerals present in the crust with sufficient concentration, taking into account as well future annual projected production.

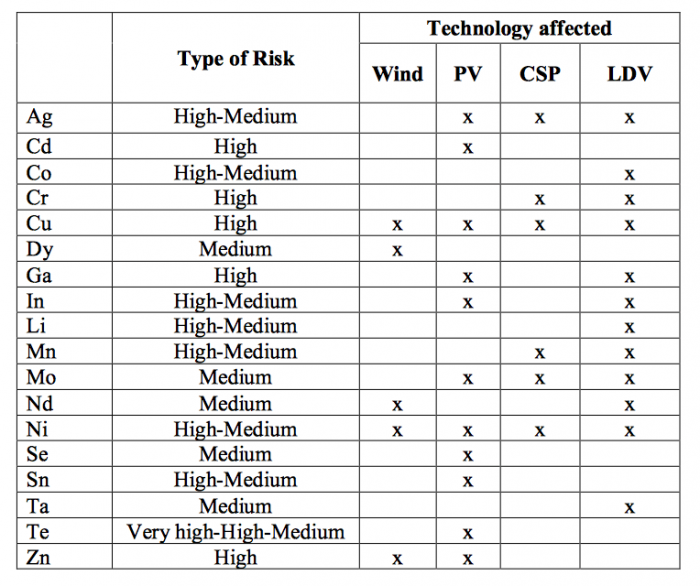

With this approach, possible constraints or bottlenecks for wind, photovoltaics (PV), concentrated solar power (CSP) and light duty vehicles (LDV) have been identified and three risk categories have been defined: very high, high and medium.

Being the very high category defined as cumulative demand exceeding current known resources, a high category defined as cumulative demand exceeding current known reserves, and medium category defined as annual demand exceeding annual expected primary production.

Via Guiomar Calvo

In this figure cumulative material demand (from 2016 to 2050) for each green technology and for the rest of the sectors is represented (vertical axis in logarithmic scale), as well as available information regarding reserves and resources.

Using silver as an example, over 1 million tonnes could be needed from 2016 to 2050, corresponding 34%, 2.5% and 0.9%, respectively, to solar photovoltaic (PV), electric vehicles, and concentrated solar power (CSP), with the rest used in other sectors. Also noteworthy is that demand may exceed available reserves in some elements (silver, lithium, indium or cobalt, among others) while demand only may exceed resources in the case of one single element (tellurium).

Considering all the green technologies analyzed, electric vehicles will probably demand the largest quantities of critical materials. Constraints are mainly focused on metals for battery manufacturing such as lithium, cobalt, and nickel. Additionally, there could be constraints regarding the manufacturing of steel alloys that need chromium or molybdenum and with certain electric and electronic equipment.

Elements that present a higher risk of generating bottlenecks in the future are tellurium, silver, cadmium, cobalt, chromium, copper, gallium, indium, lithium, manganese, nickel, tin, and zinc. The technology in which each of these elements is used can be seen in the following table.

Credit: Guiomar Calvo

It is important to emphasize that some of these elements have been already labeled as critical by national and international organizations, such as the USGS, BGS, or the European Commission, but not all of them altogether. The main difference with the approach used in this study is that we are considering not only the use of those elements in green technologies and in other sectors but also the geological availability compared to the estimated future production trends, aspects which usually are not addressed in these criticality assessment reports.

There are many ways to overcome the bottlenecks detected in this study; one of the most straightforward ones is by increasing recycling rates. For instance, the case of lithium is especially relevant as the current recycling rate is well below 1% and, as many studies address, this element has a notable future importance for storage systems. The bottleneck identified for lithium could be delayed to well beyond 2050 by increasing the recycling rate by 2050 to only 4.8%. It is also noteworthy how relatively small recycling efforts could avoid the appearance of bottlenecks for certain materials such as manganese, neodymium or tin, which would require annual growths of around 0.1%, or silver or dysprosium, of less than 1%.

As observed during the research, with the implementation of green technologies, there is going to be a shift from fossil fuels to raw material dependency. For this reason, having a better understanding of what materials are used in each green technology might become critical from a supply-side point of view. Still, if current material demands and recycling quotes continue in a business as usual scenario, the transition towards a low carbon economy will be threatened by the availability of certain commodities. Therefore, if green technologies want to be really sustainable, more efforts in dematerialization, substitution, and recycling must be done.

These findings are described in the article entitled Material bottlenecks in the future development of green technologies, recently published in the journal Renewable and Sustainable Energy Reviews. This work was conducted by Alicia Valero and Abel Ortego from the Centre of Research for Energy Resources and Consumption, and Antonio Valero and Guiomar Calvo from the Universidad de Zaragoza. This research has been carried out under the framework of MEDEAS project (Grant agreement no. 691287; H2020 programme) and under the ENE2017-85224-R project (Spanish Ministry of Economy, Industry, and Competitiveness).