The golden era of electric mobility may be upon us. In 2016, ~160,000 plug-in electric vehicles were sold in the US. To further achieve wide market penetration, the US Department of Energy and the Advanced Battery Consortium proposed that electric vehicles with 500 km driving range are required. That corresponds to 235 Wh/kg and 500 Wh/L energy density at the battery pack level, or 350 Wh/kg and 500 Wh/L at the cell level.

Current Li-ion batteries with graphite anodes, which have low theoretical capacity (372 mAh g-1), cannot satisfy the demand of high-performance battery systems. In this regard, silicon (Si) has received much attention, considering its highest theoretical capacity for lithium storage (4200 mAh g-1 for Li4.4Si). However, Si suffers from a fast capacity fade due to its large volume (>300%) change and pulverization during the lithiation and delithiation processes.

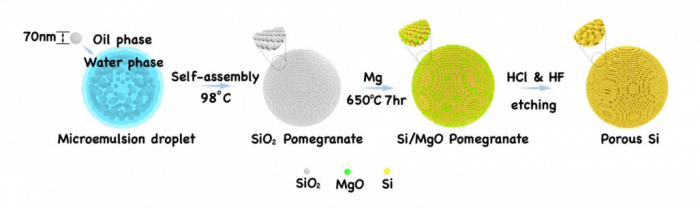

There has been significant progress toward understanding and mitigating the capacity fade in Si-based anodes, such as exploiting nanostructured electrodes, surface coatings, additives, and novel binders. However, most nanostructured Si materials must be prepared by high-cost processes that are difficult to scale up. In this regard, a new approach has been developed to obtain spherical micrometer-sized silicon with unique porous structure by using a microemulsion of the cost-effective silica nanoparticles and magnesiothermic reduction method.

Figure 1. Schematic illustration of the preparation process of the porous Si developed in this work. Republished with permission from Elsevier from https://doi.org/10.1016/j.nanoen.2018.05.048.

The concept of the design takes advantage of the nano/microstructure fabrication, which brings synergistic effects to the structural stability and the electrochemical behavior of electrode materials. And the use of the cost-effective starting materials of silica nanoparticles enables the lower cost of application. The spherical micron-sized p-Si particles prepared by this approach consist of highly aligned nano-sized silicon and exhibit a tap density close to that of bulk Si particles in favor of high volumetric capacity.

More importantly, the preserved void space created by the removal of the MgO phase can effectively accommodate the volume change of silicon and thus mitigate the breakdown of the SEI layer, which in turn endows the good long-term stability. Furthermore, the well-distributed carbon coating on the surface and inside the secondary particles is favorable for the improvement of electronic conductivity and the structural integrity. The p-Si/C electrodes deliver a high reversible capacity of 1467 mAh•g-1 at 1C rate (1C=2600 mA•g-1), good rate capacity, and superior cycling performance up to 370 cycles. Furthermore, thick micro-Si electrodes with an areal capacity of 3 mAh/cm2 demonstrate good cycling performance.

The superior electrochemical performance and cost-effective synthesis approach proved that this novel microsphere silicon composite is a promising candidate for next-generation anode material for high-energy Li-ion batteries.

These findings are described in the article entitled A Novel Approach to Synthesize Micrometer-sized Porous Silicon as a High Performance Anode for Lithium-ion Batteries, recently published in the journal Nano Energy. This work was conducted by Haiping Jia, Xialin Li, and Ji-Guang Zhang et al of Pacific Northwest National Laboratory.