A sandwich panel is a multi-layered structure which results from the assembly of two face sheets and a softcore, where the face sheet is relatively thin and has high strength and stiffness while the core is comparatively thick and has a low density. Sandwich structures include honeycomb, corrugated and lattice truss core structures.

These structures are widely used in automotive, marine and aircraft industries due to their superior stiffness-to-weight ratio and excellent thermal insulation properties. Hypersonic aircraft structure is not only subjected to various mechanical loads but also exposed to the thermal and noise environment caused by aerodynamic heating and aerodynamics. It is of significance for designers to understand the vibro-acoustic characters of the sandwich structures in a thermal environment to suppress the noise and protect the aircraft systems.

In order to have a deep detailed understanding of sandwich structure, a precise analytical modeling is required. Recently, Prof. Yu, Dr. Li and Dr. Zhao from Department of Astronautic Science and Mechanics, Harbin Institute of Technology (HIT), China, published a couple of works on the vibro-acoustic responses of a sandwich panel in a thermal environment by using piecewise shear deformation theory. The governing equations are firstly obtained by using Hamilton’s principle. Then the natural frequencies and corresponding modes are obtained by solving eigenvalues and eigenvectors.

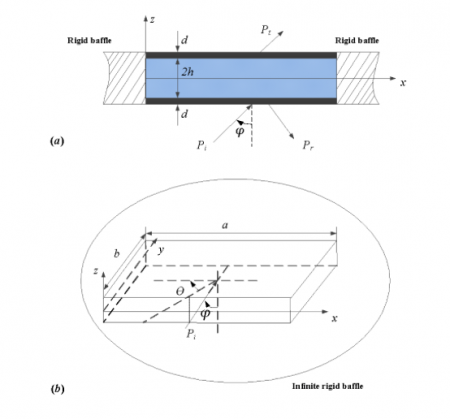

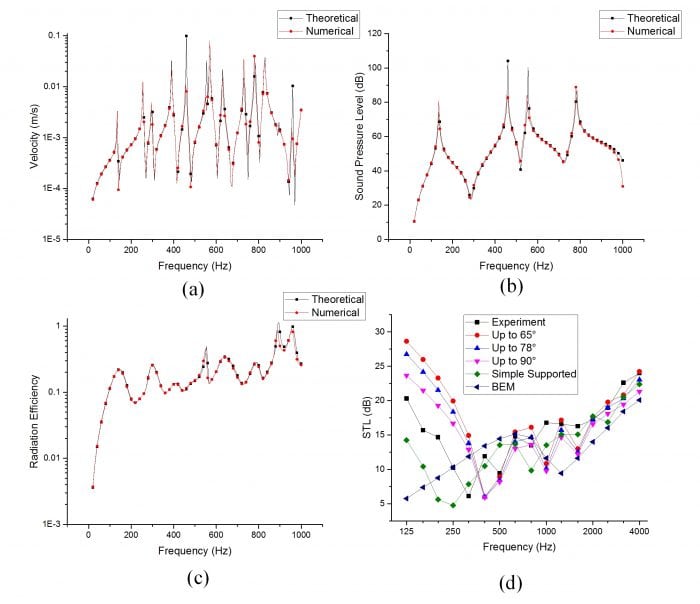

Thermal buckling temperatures and corresponding modes are obtained to investigate the buckling characteristics of the sandwich panel. The vibration response is obtained by applying the mode superposition method. Finally, the sound pressure distribution and sound radiation efficiency are obtained by applying the Rayleigh integral. Sound transmission loss (STL) of the sandwich panel is obtained by plane wave propagation method as shown in Fig. 1. The proposed analytical modeling is validated by numerical simulations and experiments as shown in Fig. 2. The vibro-acoustic characters of the sandwich panel in a thermal environment are investigated in detail.

Fig. 1. Model of sound transmission through a sandwich panel: (a) Side View; (b) Global View. (Reposted with permission from Elsevier)

Fig. 2 Validations of the analytical modeling by numerical simulations and experiments: (a) Velocity; (b) Sound pressure level; (c) Radiation efficiency; (d) Sound transmission loss. (Reposted with permission from Elsevier)

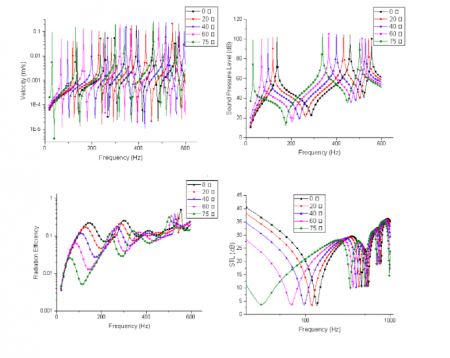

This work presents the study on the influence of thermal effects as shown in Fig. 3 on dynamic and acoustic radiation characteristics of a fully clamped rectangular sandwich panel. For the simply supported boundary condition, the study Sound transmission loss of composite and sandwich panels in thermal environment was published in Composites Part B: Engineering (2018, 133, 1-14). The analytical modeling can be widely applied to other laminated and composite structures.

It can be noted that the natural frequencies of the sandwich panel decrease as the temperature increases and the mode shape interchange is observed for the orthotropic materials. Therefore, the peaks of structural and acoustic responses move to the low-frequency domain with the increment of the temperature. Besides, the first natural frequency is affected more evidently than the higher natural frequencies. The peaks of velocity responses increase while the radiation efficiency of the sandwich panel decreases with the increment of temperature.

The peaks and the dips of the STL tend to decrease and flow to the lower frequencies with the increment of the temperature and the low-frequency range is affected more seriously than high frequencies. The first dip corresponding to the minimum of the STL flows to the high frequency. The sound insulation property of the sandwich panel is improved as the thickness of the core increases. STL curve becomes smooth when the panel dimension is increased and the infinitely large sandwich panel provides an upper limit STL for a finite panel.

These findings are described in the article entitled Vibro-acoustic response of a clamped rectangular sandwich panel in thermal environment, published in the journal Applied Acoustics. This work was led by Xiangyang Li from Harbin Institute of Technology.

Fig. 3 The influence of the temperature on the vibro-acoustic responses: (a) Velocity; (b) Sound pressure level; (c) Radiation efficiency; (d) Sound transmission loss. (Reposted with permission from Elsevier)

These findings are described in the article entitled Vibro-acoustic response of a clamped rectangular sandwich panel in thermal environment, published in the journal Applied Acoustics. This work was led by Xiangyang Li from Harbin Institute of Technology.