Heat transfer is governed by three mechanisms: conduction, convection, and thermal radiation. Conventionally, thermal radiation is often neglected in heat transfer analyses since, under most practical circumstances, its contribution is negligible compared to that of conduction or convection. However, at times, thermal radiation can be a significant or even predominant form of heat transfer, such as in high-temperature systems or in outer space.

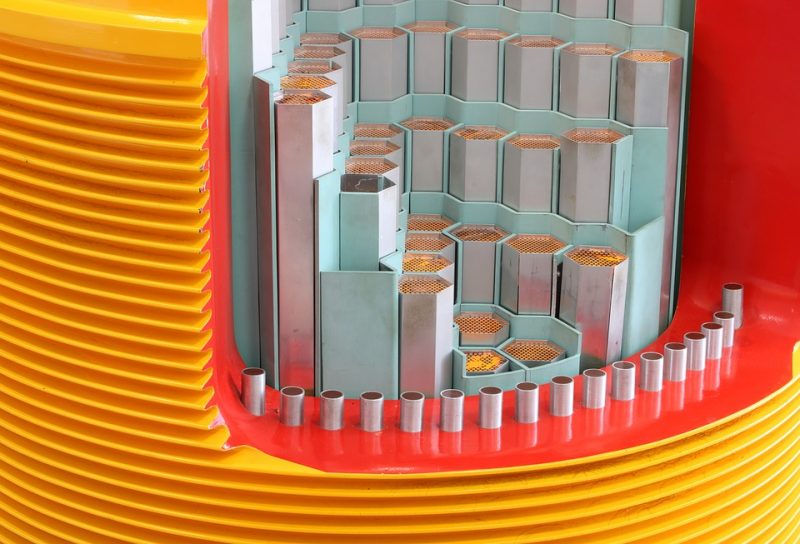

The capacity of a surface to emit heat via thermal radiation is based on its property known as the emissivity. To achieve higher efficiencies, heat exchangers and reactor core components of future reactors are designed to operate at temperatures several hundred degrees Celsius hotter than the conditions of existing designs. At these higher temperatures, thermal radiation plays a much larger role than before.

However, little research has been conducted to see how the emissivities of reactor-alloy surfaces evolve over time as they are exposed to their intended environment. Next-generation reactor designs feature extraordinary capabilities but do so by relying on exotic working fluids. For example, liquid sodium coolant enables highly efficient fuel breeding cycles, while both molten salt and helium gas coolants enable unique passive safety mechanisms. Additionally, at elevated temperatures, the supercritical-CO2-based Brayton thermodynamic cycle features a far greater theoretical efficiency than the conventional water-based Rankine cycle implemented in today’s light-water reactors [1]. While these unique media of liquid sodium, molten salt, helium gas, and supercritical CO2 each offer unique capabilities, exposure testing of materials in these media requires highly specialized custom-built facilities.

In our study, we measured the emissivities of several reactor alloys before and after exposure to environments relevant to next-generation reactors. Our environment of supercritical CO2 (relating to supercritical CO2 thermodynamic cycles) and our environment of impurity-rich helium gas (relating to high-temperature gas reactor coolant loops) were both highly oxidative for their respective alloys. These new oxidized alloy surfaces featured much greater emissivities than those of the unexposed control, indicating that the emissivity of alloys in related reactor environments may change significantly through operation.

Our environments of liquid sodium (relating to liquid sodium reactor coolant loops) and molten salt (relating to molten salt reactor coolant loops) yielded relatively insignificant changes to their respective alloy emissivities, with the exception of molten salt-exposed 316 stainless steel, which saw moderate increases. Chromium-rich alloys, such as 316 stainless steel, are susceptible to surface chromium depletion during molten salt exposure [2]. Chromium depletion may have contributed to the increased emissivity that we observed in our salt-exposed, chromium-rich, steel alloy and did not observe in our salt-exposed, nickel-based alloy which has less chromium content.

An accurate understanding of heat transfer parameters, such as emissivity, will enable the precise design and operation of advanced nuclear reactors. Our study provides the initial steps towards the capability to accurately predict the emissivity of alloy surfaces as they experience various potentially corrosive high-temperature environments. The data can be used for computer models that analyze the state of reactors for both normal operating conditions and critical accident scenarios. Accurate models with well-informed input parameters can make the next generation of nuclear reactors safer, cleaner, and more efficient.

These findings are described in the article entitled Impact of corrosion on the emissivity of advanced reactor structural alloys, recently published in the Journal of Nuclear Materials. This work was conducted by J.L. King, H. Jo, A. Shahsafi, K. Blomstrand, K. Sridharan, and M.A. Kats from the University of Wisconsin-Madison. Thanks to Mikhail Kats and Alireza Shahsafi for their help in reviewing this article.

References:

- G. Angelino, Carbon dioxide condensation cycles for power production, J. Eng. Power (1968) 287e295.

- Koger J.W. (1974) Chromium Depletion and Void Formation in Fe—Ni—Cr Alloys During Molten Salt Corrosion and Related Processes. In: Fontana M.G., Staehle R.W. (eds) Advances in Corrosion Science and Technology. Springer, Boston, MA