Coffee roasting in an industrial plant represents one of the most critical issues in the food industry, as the final flavor of the beverage will strongly depend on the choice of the right blend of raw materials coming from different countries and the right end-time of the process. Although wet and dry post-harvesting processes of coffee beans may affect the final taste of the beverage, essentially the flavor and aroma of the in-cup coffee are influenced strongly by roasting.

Another interesting issue is related to the quality standardized by the consumer’s needs. The consumer is accustomed to a certain type of taste that expects from that brand and he always wants to get it. A different taste will be perceived as a product of inferior quality. For these reasons, the final taste should maintain the same quality and characteristics over time despite the seasonal variety of raw materials (green coffee) and interchangeability of the suppliers due to market reasons. In this phase, the experience of the roast-master still plays an important role.

His ability and experience over time together with the essential work of the panel team working in the plant, permit to select the right blends of coffee from different origins and to choose the right roasting conditions as air temperature and time of the process in the industrial roaster, by using a step-by-step feedback process.

Essentially the roast master uses his experience and sensorial ability in examining color and flavor of a sample taken during roasting at predefined intervals. Browning of the green coffee beans and developing of characteristic flavor allow him to stop the process at the right time. Automation that exists in the coffee industry, is essentially limited to controlling the temperature of the drum, roasting conditions (recirculation of air), process timing, with setting up of roasting profiles. Senso-instrumental techniques for color and in particular odor measurement are recently gaining attention in the scientific community as cheap, versatile, devices mimicking humans senses, in the food industry.

Color has been extensively used in coffee roasting and devices able to evaluate darkening of coffee beans are well-known tools to estimate the grade of roasting of the beans. Apart from cameras, several approaches have been tested in literature with laboratory-scale roasters equipped with analytical instrumentations, but numerous limitations were not surmountable as scalability issues from bench scale to industrial roaster, the use of expensive devices, and the need to handle a large dataset of variables.

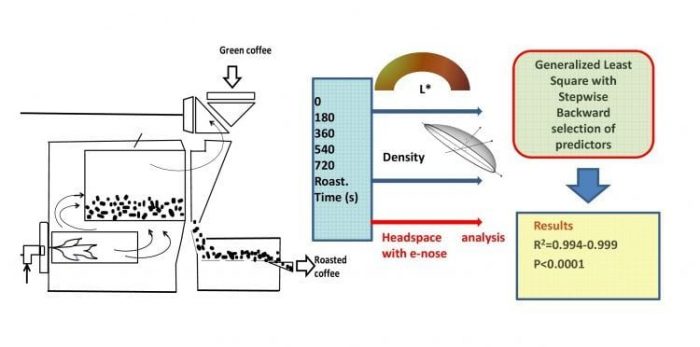

Graphical abstract: a sketch of the work in brief (Credit: Pasquale Giungato)

Few works have analyzed the other sense used by the roast-master: olfaction in real conditions of work. An electronic nose, a device mimicking human olfactory sense, is not affected by air turbulence, do not need an illuminant, is able to collect a small amount of air from the roaster drum without affecting the process and analyze it to verify the development of the characteristic flavors of the final product. Moreover, it handles a relatively small dataset of variables.

However, the device needs a robust training to obtain standardized responses reaching target quality parameters needed by the coffee industry and a selection of the data produced as some of them are redundant or noise.

The term “electronic nose” was introduced for the first time in the late 1980’s and used in conferences but the best definition is attributable to Gardner J.W. and Bartlett P.N.: “an instrument composed of an array of chemical sensors with partial specificity and a pattern recognition system able to recognize odors also in complex mixture”. Human olfaction apparatus was the model towards efforts of researchers were made in the attempt of reproducing an analytical device mimicking human sense. For that reason, the electronic nose is generally composed of a sampling system (pumps), a matrix of sensors and a pattern recognition system mimicking the neuronal apparatus. Some electronic noses are “active” devices if equipped with a pumping system that actively loads the sampled air into the array chamber, as in this case. In an array of sensors useful discrimination and regression capabilities could be achieved without the use of highly specific receptors like those working in the human nose, but using the information coming from all the devices together.

In this paper, the response of an electronic nose sampling the headspace of roasted beans, was correlated with brightness (a color parameter) and mean density of the beans (measured one by one by using the assumption that the geometric shape was almost that of a triaxial ellipsoid), by using the generalized least square regression in combination with a stepwise backward selection of predictors.

Figure 1: how works the assumption that the geometric shape of the beans was almost that of a triaxial ellipsoid; lower bean: green coffee, upper bean: roasted coffee (Credit: Pasquale Giungato)

The choice of such a statistical treatment of data come from experience in data mining and historical series of the authors. In the study of economic data, numerous noising information can affect correlation statistics, as economic behavior in populations may depend from an enormous number of variables that cannot be isolated. The same issue applies in the case of a sensor array: redundancy and collinearity affect the discrimination and regression capabilities of an electronic nose’s array, as most of the sensors are generally made with the same technology for economic reasons, and the response of different sensors sometimes is quite the same also with different samples took at different roasting degrees.

The selection of predictors essentially provided to the authors the statistical tool used to select the right sensors of the array useful for prediction of roasting degree, excluding those ones which gave noise, not-useful signals or redundancy.

To avoid scalability issues, roasting took place in an industrial plant using two Arabica (Brazil and Costa Rica) and two Robusta (Vietnam and India) origins individually loaded to test also the behavior of the device in presence of blends coming from different countries.

Figure 2: roasted coffee beans, the micrometer used for density measurement and a color checker for calibration and color measurement (Credit: Pasquale Giungato)

Correlation between the proxies of the roasting degree (brightness and density of the roasted beans) and the electronic-nose responses (selected signals of the array) showed R2 ranging in the interval 0.994–0.999, with statistical significance p < 0.0001.

This means that the electronic nose may forecast both color and density of the coffee beans, and it is able to monitor the process, predicting roasting degree of the beans, the end-time of the process, with no need of chemical analysis of off-gases, cameras, illuminants, thermocouples.

The authors believe that the present approach has the potential to be used effectively in the online monitoring of the process in industrial plants, also in presence of blends, instead of roast master and in synergy with the existing automated devices used in roasters.

These findings are described in the article entitled Evaluation of Industrial Roasting Degree of Coffee Beans by Using an Electronic Nose and a Stepwise Backward Selection of Predictors,(2017) Food Analytical Methods, 10 (10), pp. 3424-3433. DOI: 10.1007/s12161-017-0909-z. This work was led by P. Giungato, E. Laiola, and V. Nicolardi from the University of Bari “Aldo Moro” and the University of Foggia.