Industrial biotechnology aims to use bioprocessing of sustainable agriculture products, such as starch, fatty acids and/or cellulose, to produce bulk chemicals including polymeric materials and biofuels.

However, bio-based products derived from microbial conversions such as biochemicals, bioplastics, and biofuels are still too expensive due to their high production cost compared with their chemical counterparts. The high production cost of bioprocessing is mainly associated with the following issues:

- The price of raw materials (substrates), e.g. glucose from hydrolysis of starch, has increased very quickly.

- Bioprocessing requires a large amount of fresh water, making the water shortage even worse.

- Most of the fermentation processes (bioprocessing) are run discontinuously to avoid microbial contamination, resulting in low production efficiency.

- The energy-intensive sterilization of the fermentors and piping systems, as well as the medium, is a very expensive, energy-intensive process.

- Also, the investment to purchase stainless steel for bioprocess facilities is heavy.

- Procedures to remain contamination-free and batch processes make bioprocessing very complicated, leading to increased costs for bioproduction.

All of the difficulties from current industrial biotechnology practices could be attributed to the production of microorganisms that are susceptible to contamination by other microbes. For example, common industrial strains, such as E. coli, Bacillus spp., Corynebacterium glutamicum, Pseudomonas spp., and yeast, are grown under mild conditions at weak acidic or neutral pH of 5-7 and 30-37oC. When supplemented with yeast extract, the mild condition allows most microorganisms in the air, water, and soils to grow. Production facilities have to be sealed and completely sterilized to prevent any microbial invasion. This procedure dramatically increases the complexity of the bioprocesses, leading to high production cost.

To make industrial biotechnology as competitive as the chemical industry, it is urgent to develop low-cost bioprocessing technology, namely, the “Next Generation Industrial Biotechnology” or “NGIB.” In such technology, low energy and freshwater consumption, as well as contamination-free, continuous fermentation processes, are required, in addition to using low-cost substrates. NGIB allows bioprocessing to be conducted under unsterile (open) conditions using ceramic, cement, or plastic bioreactors in a continuous way; it should be an energy-, water-, and substrate-saving process with a convenient operation procedure.

The foundation for simplified NGIB is microorganisms that resist contaminations by other microbes. These microorganisms should also be able to grow rapidly. There should also be molecular engineering methods and tools for improving performances and for producing multiple products. As a platform production strain, the microorganisms should have their genome information fully available. Extremophilic bacteria, including acidophiles, alkaliphiles, psychrophilic, thermophiles, xerophiles, and halophiles, as well as methanotrophs, gaseous substrates, or cellulose utilizers, should be able to grow under some unique conditions that prevent contamination by normal microorganisms.

One example is a rapidly-growing halophilic bacteria inoculated under high salt concentration and alkali pH. Halophilic microorganisms usually inhabit hypersaline environments or the sea. They are sources for discovery of bioactive compounds, including antioxidants, sunscreen, and antibiotic compounds, and compatible solutes that are useful as stabilizers for biomolecules or stress-protective agents.

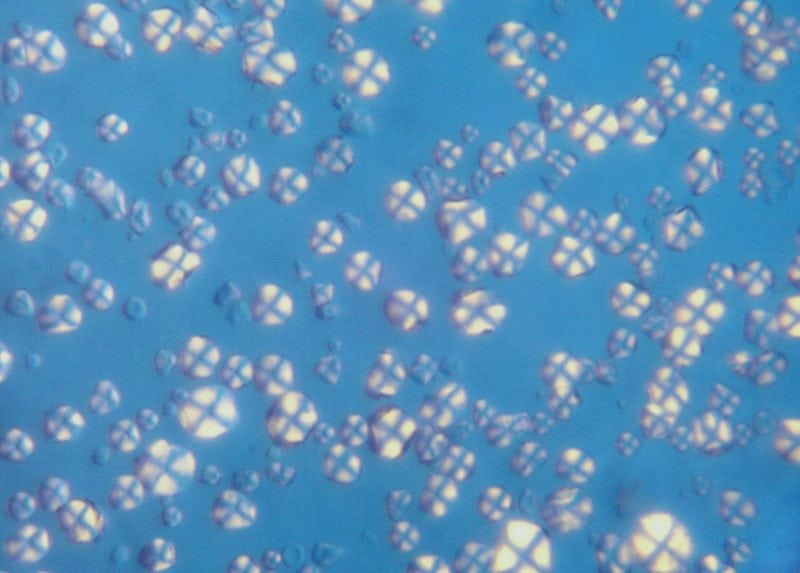

Recently, alkaphlic halophiles have been successfully used to develop seawater-based fermentation processes for the production of polyhydroxyalkanoates (PHA) under open and continuous processes. PHA applications are limited, due to their high cost of production. Halomonas bluephagenesis, a halophile isolated from a salt lake in Xinjiang/China, is a hyper-PHA producer able to grow in unsterile conditions with a continuous fermentation process. However, during the pilot-scale production of PHA, the low conversion rate of substrate to PHA, unstable PHA productivity, and high cost of downstream processing posed challenges. De novo sequencing of H. bluephagenesis was completed, and the 4.09 Mb genomic information with GC 52.57% was decoded, paving the road for developing genetic manipulations of H. bluephagenesis.

Technologies have been developed including effective conjugation for plasmid transformation, efficient expression systems for relatively high-level expression of proteins, and knockout methods for markerless gene replacement or deletion, allowing for possible property improvements and multiple product production by the platform strain. H. bluephagenesis and similar strain Halomonas campaniensis LS21 are able to grow in seawater under open unsterile and continuous conditions without contamination for weeks to months.

Since NGIB does not require high temperature and high-pressure steam for sterilization, bioreactor constructions become less expensive, as plastics, cerements, and/or ceramics can all be used to build bioreactors. Since sterilization is avoided, fermentation operation can become much more simple, and highly-trained microbial fermentation engineers may not be needed. As the extremophiles are more robust, they are more stable under changing dynamic growth conditions, and automation can become more realistic. NGIB-based fully automatic bioprocessing plants can be expected.

These findings are described in the article entitled, Next generation industrial biotechnology based on extremophilic bacteria, recently published in the journal Current Opinion in Biotechnology. Guo-Qiang Chen and Xiao-Ran Jiang from the School of Life Sciences, Tsinghua University, conducted this work.