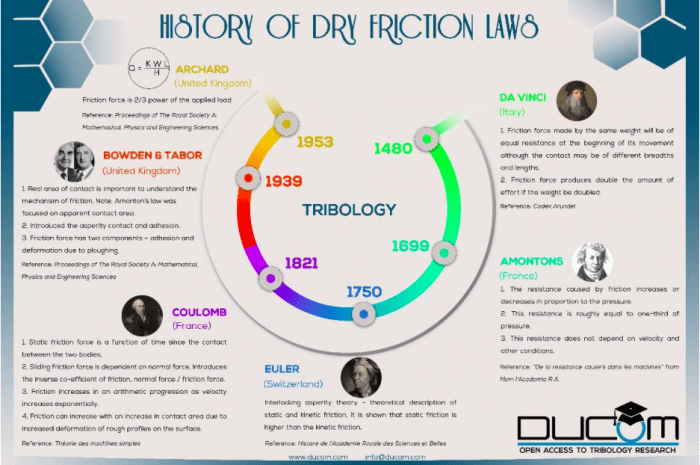

Since the advent of tribology, conflicting fundamental laws regarding the relationship that exists between friction and contact area in dry sliding condition have existed, which is further described in Figure 1.

For example, during the late 1400s, Leonardo da Vinci found that the friction that exists between two surfaces cannot be influenced by its area of contact. By 1699, scientists like Amontons remained in agreeance with da Vinci’s explanation.

Figure 1. Illustration of the chronology of events associated with dry contact friction laws developed from the 15th until the 20th century. Credit: Ducom

However, this theory began to be questioned during the early 1800s by Coulomb who determined that, depending on the deformation that exists on the profiles of the surfaces that control the contact area, friction can increase or decrease. Furthermore, by the turn of the 20th century, researchers Archard, Bowden, and Tabor found that the friction is, in fact, proportional to the real contact area through the use of the Hertzian contact model.

Understanding the Role of Friction in Dry Sliding

Since these initial observations, the definition of contact area has been refined into two categories of apparent contact area, which closely relates to the observations made by both Da Vinci and Amontons, and real contact area, that refers to the observations by Coulomb, Archard, Bowden, and Tabor.

Despite the efforts made by these pioneer scientists, few experimental investigations have been able to accurately report the mechanisms elucidated by friction as a result of changes that occur in either the apparent or real contact area in dry sliding. Furthermore, there is also a lack of experiments that have been performed at high temperatures to determine the mechanism of friction at these external conditions.

Investigating a Novel Tribology Test Method

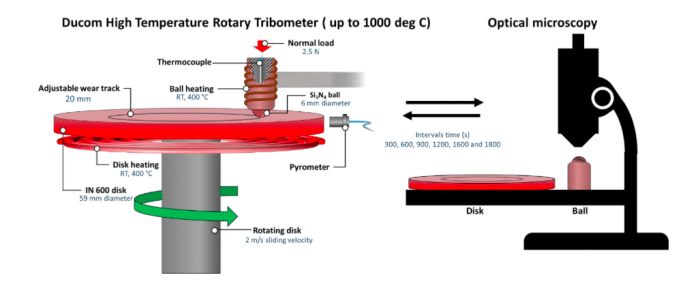

In the study discussed here, an ex-situ tribology test method is evaluated for its ability to provide information on the relationship that exists between friction and apparent contact area at a high temperature of 400 °C.

Herein, a Ducom High-Temperature Rotary Tribometer (ball on disk) that is equipped with an open-air heating system was used. All appropriate test methods and materials are further described in Figure 2. Any wear scar images on the Inconel (IN 600) disk and silicon nitride (Si3N4) ball were captured using a high-resolution optical microscope after interrupting the friction test.

Figure 2. The test parameters involved in the Ducom High-Temperature Rotary Tribometer configured with the Ball on Disk feature. For the purposes of this high-temperature study, an open-air heating system developed by Ducom was used, whereas the ex-situ tribology test method involved the use of optical microscopy for imaging of the wear scar on ball and disk every 300 seconds. Credit: Ducom

Results

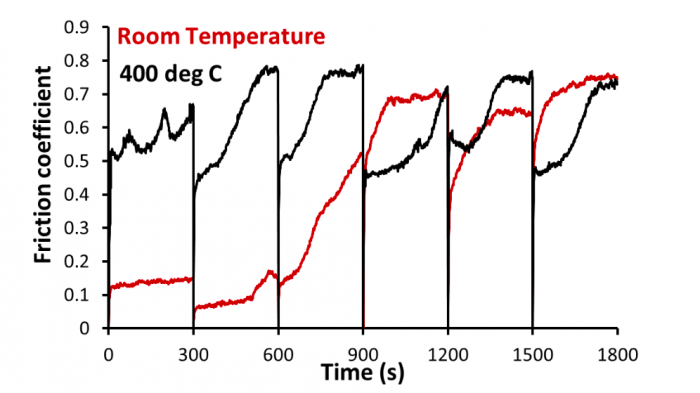

As shown in Figure 3, the friction coefficient, which is calculated as a ratio of friction force and applied load, for the Si3N4 ball and IN600 disk significantly increased following 600 seconds at room temperature (RT), whereas it this ball remained stable during the high-temperature test conducted at 400 °C.

Figure 3. The real-time evolution of the friction coefficient as a function of time for both the high and room temperature friction tests. Following every 300 seconds, the friction test was stopped and specimens were subjected to microscopy imaging to measure the wear scar on the ball and disk. Credit: Ducom

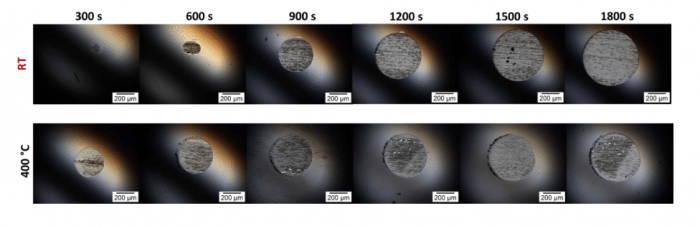

At room temperature, it was found that the wear scar image evolved from a small elliptical shape to eventually become a larger circular shape by 1500 seconds, whereas the high-temperature test caused the wear scar image to evolve from a medium to larger circular shape by the same time point.

Figure 4. The optical microscopy images of the ball wear scar every 300 seconds following the friction test. Panels at the top and bottom represent images obtained from tests at room temperature and 400 °C, respectively. Credit: Ducom

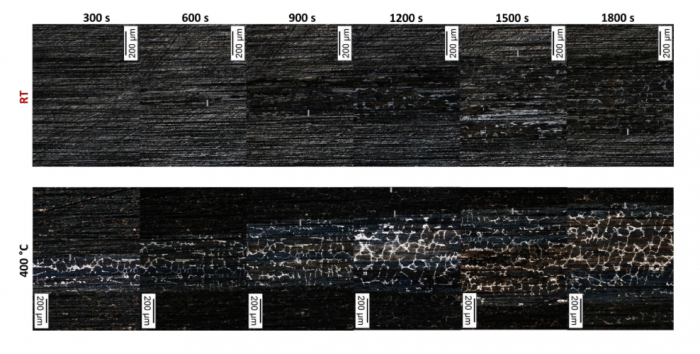

The wear track images that were captured on the disk, as shown in Figure 5, shown that at room temperature, the wear track was barely visible until 600 seconds; however, when exposed to a high temperature of 400 °C, oxide scales were found to visibly grow over time. The brittle nature of the oxide scales was evident at this ambient temperature as a result of the widening of the cracks on the surface.

Figure 5. Optical microscopy images of the disk wear scar at every 300 seconds following the friction test. Panels at the top and bottom represent images obtained from tests performed at both room temperature and 400 °C, respectively. Credit: Ducom

Conclusions

Although an in-situ test method capable of capturing the contact area and friction between metal interfaces is typically preferred, these types of methods are not currently available for investigating the metal contacts in a high-temperature test. To this end, the ex-situ test method described in this study has shown promising results for this exact purpose.

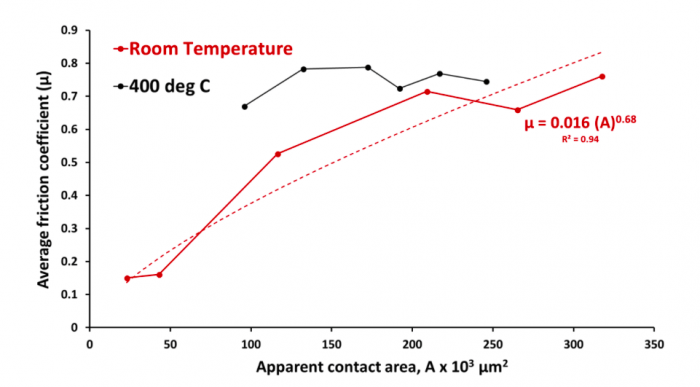

Figure 6. Changes in average friction coefficient as a function of the apparent contact area for the test at room temperature and 400 °C. The apparent contact area was calculated using the mean wear scar diameter of the ball. Herein, the average friction coefficient was plotted as a function of the apparent contact area that was obtained through calculations every 300 seconds. During the room temperature test, the friction coefficient was found to exhibit a 2/3rd – power law relationship with the apparent contact area; however, the friction coefficient remained independent of apparent contact area at 400 °C. Credit: Ducom

The preliminary test results obtained through the use of the Ducom High-Temperature Rotary Tribometer and an optical microscope shows that the friction force is proportional to the contact area for Si3N4 and IN 600 in dry contact.

However, this type of relationship is limited by the oxide layer that is formed on the disk during the high-temperature friction test. An important benefit of this interfacial layer, otherwise referred to as the third body layer, involves its ability to provide a stable friction system despite an increase in apparent contact area occurring.

The results of this study reiterate the fact that no single fundamental law on the dependence of friction on apparent contact area can exist as a result of the varying system conditions, which, in this study, was a high temperature of 400 °C.