A porous material is a medium containing pores filled with a fluid (liquid or gas). The skeletal part is usually solid. Many natural and made mediums such as rocks, soils, bones, plastic foams, fibrous materials, cement, and ceramics can be considered as porous materials.

Among these materials, such as plastic foams and fibrous, are frequently used in the automotive and aeronautic industries and in the buildings trade to reduce noise and vibration pollution. Therefore, good acoustic performance is a desirable attribute in almost all types of buildings and is particularly important for residential buildings, schools, and hospitals. The effectiveness of these porous materials in sound absorption is mainly based on their intrinsic properties.

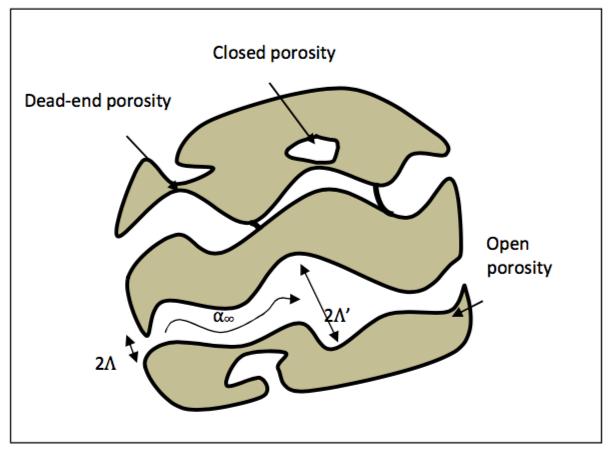

Fig. 1 – Different parameters describing a porous medium. Credit: M. Sadouki

Among these famous properties we quote:

- The porosity Φ presents the ratio of the fluid volume occupied by the continuous fluid phase to the total volume of porous material. its value is between 0 and 1. (0 < φ < 1.). The porosity can be measured directly using the pressure difference technique introduced by Leo Beranek and improved by Champoux, Stinson, and Daigle.

- The tortuosity α∞ characterizes the sinuosity of the porous space; it represents a measure of the deviation of a line. This is the ratio of the actual distance traveled between two points, including the curves encountered, divided by the distance in a straight line. Tortuosity is used by geologists to describe pore systems in the rock. For acoustic materials, tortuosity values are between [1.00 and 3.00]. A simple direct technique based on ultrasonic wave speed measurements in a material saturated by air is proposed by F. Jean et al. for measuring the tortuosity.

- The viscous characteristic length Λ represents the small values of the pore radius, while thermal characteristic length Λ’ corresponds to the size of large pore rays. The viscous dimension can be evaluated by the BET method plus an acoustical measurement.

The practical implementation of the direct methods for determination of these parameters can be complex and expensive.

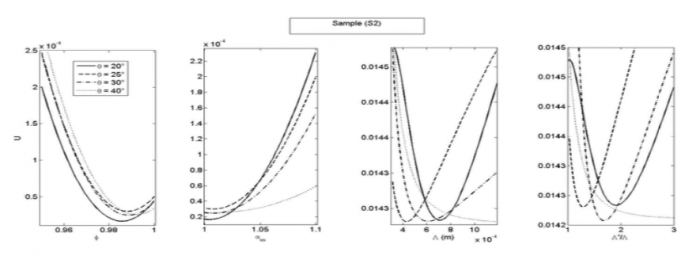

Ultrasonic technique for the evaluation of acoustic parameters of air-saturated porous material is proposed. This technique is called an indirect or inverse method, is based on measurements of obliquely-reflected ultrasonic waves from the surface of the porous medium. The values of porosity, tortuosity, viscous and thermal characteristic lengths are obtained by minimizing between the experimental and simulated reflected signals by varying these parameters until that the difference between simulated and experimental curves will be smaller (Fig.1).

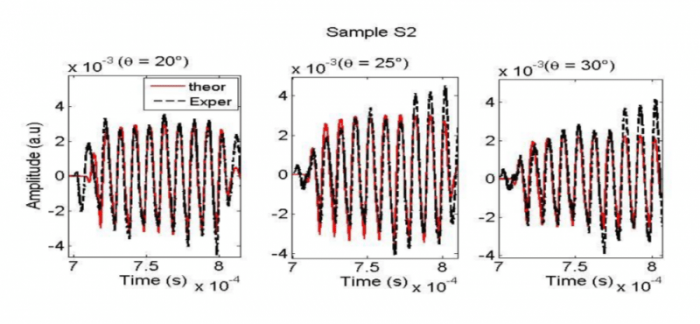

The optimized values found for the different parameters of a plastic foam sample (S2) are close to those obtained using the direct methods mentioned. A comparison between the experimental and simulated reflected signals, using the inverted values, is given in Fig. 2. The agreement between the two curves is good, which leads us to conclude that the proposed method is efficient, fast and inexpensive for the complete characterization of the porous medium saturated with air.

Fig. 2 – The optimized values of the porosity, tortuosity, viscous and the ratio of the viscous and thermal characteristic lengths of the sample (S2) for different angles of oblique incidence. Republished with permission from Elsevier from: https://doi.org/10.1016/j.apacoust.2017.12.010

Fig. 3 – Comparison between the experimental and simulated reflected signals using the optimized parameters found for the sample (S2) in different angles of oblique incidence. Republished with permission from Elsevier from: https://doi.org/10.1016/j.apacoust.2017.12.010

These findings are described in the article entitled Experimental characterization of rigid porous material via the first ultrasonic reflected waves at oblique incidence, published in the journal Applied Acoustics. This work was led by M. Sadouki in collaboration with Prof. R. Panneton and Dr. K. Verdiére from the Acoustics Laboratory of the University of Sherbrook.