Hydrothermal liquefaction (HTL) of microalgae has attracted growing interest for bio-oil production because it does not require dewatering and drying of algal biomass. However, up to now, this technology has rarely been commercialized. One of the problems impeding its industrialization is the production of wastewater (the aqueous phase product) during HTL. More than 20% of the carbon and 50% of the algae is transformed to this wastewater. The cost for wastewater treatment by traditional methods would very high and the nutrients would be wasted.

Alternatively, this wastewater may be treated as a nutrients source for algae cultivation. During the last decade, researchers have been trying to make this possible. The wastewater may be used as carbon, nitrogen, phosphorus or even the sole nutrient source to sustain the normal algae culture. But it has to be diluted by a hundred times or even higher because the concentrations of nutrients are too high, and most importantly, the high concentrations of inhibitory substances such as phenolics, heavy metals, and cyclic nitrogenous compounds.

Inhibitory effects from these compounds may be alleviated by tuning the wastewater to a desirable level by adjusting HTL process parameters (e.g., changing reaction temperature), pre-treatment of wastewater to remove or reduce the inhibitory compounds, or balancing nutrients contents in wastewater. On the other hand, isolation and selection of robust algae species or species obtained from genetic engineering and metabolic evolution would be very effective to decrease the inhibitory effects.

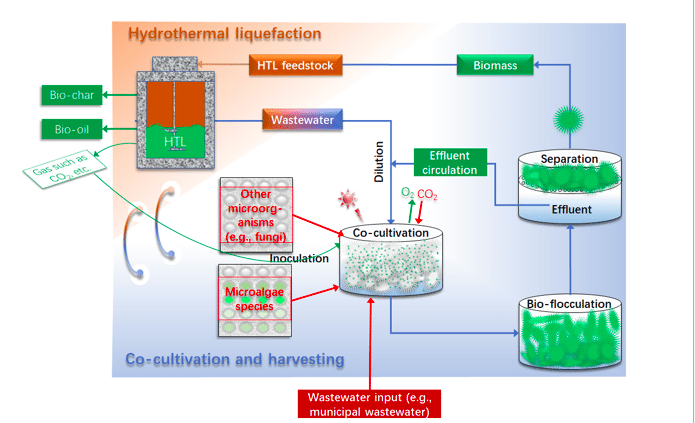

Another promising way is to co-cultivating multiple algae species or cultivating algae with other microorganisms such as bacteria and fungi. It could be more advantageous when the microorganisms could settle by itself because of bio-flocculation. For example, microalgae can by harvested by bacteria and fungi, or even by other self-flocculating microalgae species. Additionally, cultivation of multiple species (polyculture) can support the stable ecosystem of the wastewater treatment system because of enhanced biodiversity. Combining two or more of these above strategies can help realize effective detoxification.

When the treatment of wastewater and biomass accumulation are attained, a closed-loop HTL microalgae bio-oil production system may be designed to promote the industrialization of this technology. In the system, nutrients are circulating in the system from biomass to wastewater and then back to biomass with bio-oil as the main output product. Combining inputting municipal wastewater or other source of wastewater and atmospheric carbon dioxide can largely compensate for the nutrients lost during HTL because of bio-oil and bio-char production. Sunlight input help microalgae sequester carbon dioxide to synthesize biomass components (by autotrophic growth). Meanwhile, organic matters and other nutrients would support the growth of mixotrophic microalgae and other microorganisms.

Image credit: Wenguang Zhou

Before the loop can be closed, there are many works to do which include: 1) achieve effective wastewater treatment by microalgae consortia while at the same time the effective microalgae harvest; 2) clarify the influence of wastewater properties on biomass accumulations and biochemical compositions; 3) tune the HTL for high-quality bio-oil production with acceptable wastewater properties; 4) specify the inhibitory effects and study the accumulation characteristics of inhibitory toxins after times of re-circulations, and find methods to alleviate the toxicity accumulation.

These findings are described in the article entitled Use of microalgae to recycle nutrients in aqueous phase derived from hydrothermal liquefaction process, recently published in the journal Bioresource Technology. This work was conducted by Lijian Leng, Jun Li, Zhiyou Wen, and Wenguang Zhou from Nanchang University.