In-situ burning (ISB) is a conventional method in oil spill cleanup. It requires less equipment compared to manual or mechanical recovery. It is also faster and much cheaper. ISB was extensively used in the Gulf of Mexico, Deepwater Horizon Spill in 2010. But, what if the next big spill is in northern parts of Alaska, where there is a substantial possibility of finding one or another form of ice in the marine environment?

If an oil spill were to occur under icy conditions in the Arctic, in-situ burning (ISB) may be the only option for efficient cleanup. This is because the remoteness and harsh climatic conditions of Arctic are likely to make it impossible for heavy machinery to be deployed immediately after a spill to facilitate either mechanical recovery or the use of dispersants, which are the two other primary response methods for off-shore oil spill cleanup.

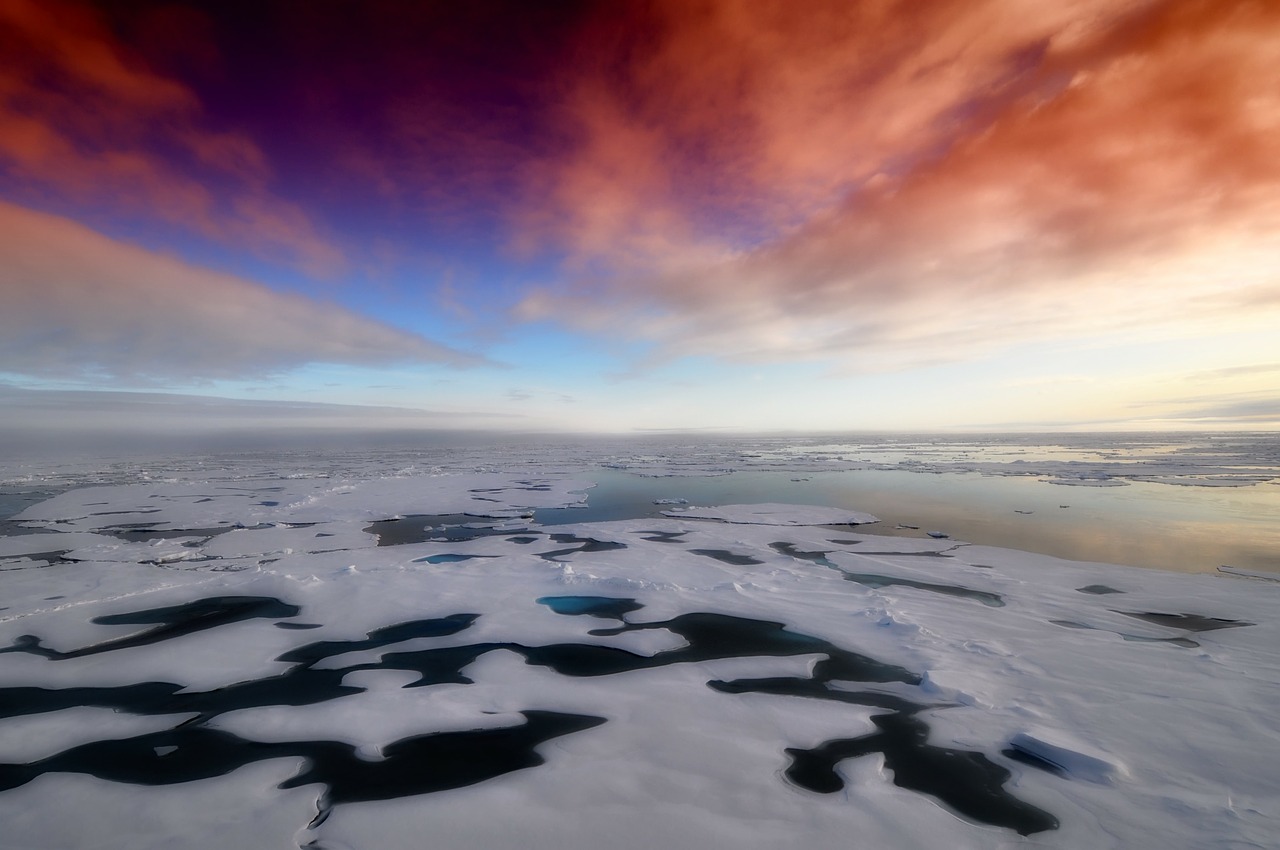

There are several different marine activities that can lead to oil spills in the Arctic region and the recently enhanced activity due to now-longer open ice seasons in the region is expected to increase the probability of an oil spill. In addition, oil companies have spent over $600 million in the recent last years in oil exploration in the Arctic. Analysts predict that the investment in oil exploration in the Arctic will reach more than $100 billion with many other countries (including the US) investing massive resources.

In situations where ice is on water and oil is between ice floes, unique and unexplored physical processes come into play by use of ISB. Melting of ice because of the heat from the flames causes the geometry of ice to change. Specifically, the diameter of the burning fire increases as the burning continues. There, thus, exists a strong coupling between the burning rate and the geometry change of the pool and cavity.

To explore this unique phenomenon, experiments were performed in circular ice cavities of varying diameters, ranging from 5 to 100 cm. The change in shape of the ice cavity and the oil layer thickness were recorded using a combination of visual images, mass loss, and temperature data along the centerline and edge of the cavity. The results showed how ice influenced the burning rate, as such for small fires in ice (around 5-10 cm in diameter) reduced burning rates were observed. This was compared to normal pool fires of similar size in a temperate environment. The icy walls create a significant heat sink causing notable lateral heat losses that is a disadvantage for the energy balance of the burning oil. However, if the fire size of larger than 25-50 cm is considered, the burning rates and the amount of oil removed by burning will be similar to such fires in temperate ambient.

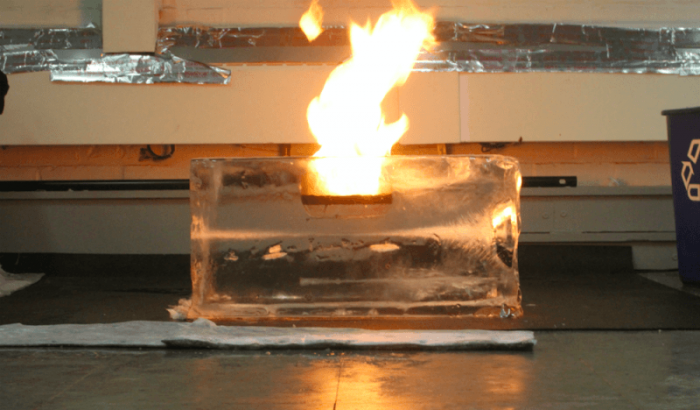

Burning crude oil in an ice cavity with an initial diameter of 25 cm. Slight boilover is occurring in this photograph. Image courtesy Hamed Farmahini Farahani

Another fascinating aspect of this research was the unique shape the ice walls were melting, and it became a new path for more research. The burning fuel near an ice body was observed to penetrate radially into the ice to shape a lateral cavity inside the ice. A hypothesis was proposed that the convective motions within the liquid-phase of the fuel are the culprits for transferring the heat of the flame toward the ice and melting it.

Side view of a crude oil layer burning inside an ice cavity. Image courtesy Hamed Farmahini Farahani

To evaluate this hypothesis, a parametric experimental study on melting of ice adjacent to liquids exposed to various heat fluxes from above was conducted in order to understand the role of liquid properties in the formation of cavities in ice. An experimental setup was designed to measure the melting rate of the ice and penetration speed of the liquid fuels similar to the lateral cavity formation problem observed in ISB experiments. Lateral cavity formation is identified as a key factor in reducing the removal efficiency of ISB. The experiments were conducted in a transparent glass tray (70mm×70mm×45 mm) with a 20mm thick ice wall (70mm×50mm×20 mm) placed on one side of the tray. Liquids in the tray (water, n-pentane, dodecane, n-octane, m-xylene, and 1-butanol) that were adjacent to the ice wall were exposed to varying heat fluxes mimicking flame heat feedback from a pool fire. The results of ice melting rate among different liquids were found to vary significantly.

From the experimental results, it can be seen that an increase in the heat flux decreased the melting time, increased the melting front velocity, and decreased the cavity width. Comparison of the experimental results and the liquid properties showed that liquids with higher melting front velocities had relatively lower viscosity and higher surface tension coefficient. For example, n-Octane and m-Xylene melted the ice much faster compared to other liquids tested at the same heat flux exposure. The exposure of the liquids to the radiative heat flux led to a temperature difference between the liquid and the ice, thereby creating a heat transfer pathway towards the ice that provided the required energy for the melting.

The results of a scaling showed that a grouping of the liquid properties, consisting of viscosity, surface tension coefficient, thermal conductivity, and density of the liquids, were recognized to be the most influential parameters in determining the magnitude of the surface velocity and consequently the melting front velocity. The findings of such studies are important for oil spill response strategies.

These findings are described in the article entitled Convection-driven cavity formation in ice adjacent to externally heated flammable and non-flammable liquids, recently published in the journal Cold Regions Science and Technology. This work was conducted by Hamed Farmahini Farahani from the Worcester Polytechnic Institute and the University of Maryland, Yanyun Fu from Tsinghua University, Grunde Jomaas from the University of Edinburgh and the Technical University of Denmark, and Ali S. Rangwala from the Worcester Polytechnic Institute.