Bypassing the conventional lab-based, time-intensive, protocol-oriented multistep methods of food quality assurances, recent interests have been tremendously focused on rapid, onsite, and accurate quality checkups. These are majorly based on biosensor systems for the determination of exclusive indicators responsible for food quality. In this context, liquid food items are more susceptible to embracing the microbial form during the commercialization process. Therefore, for the safety of consumers, it is very important to segregate good-quality liquids from the spoiled before purchasing or consuming.

Since milk has been a part of various traditional and contemporary servings across the globe due to its rich nutritional contents of proteins, carbohydrates, fats, essential vitamins, and minerals including calcium, phosphorus, etc. It became an important option for commercial activities (Coimbra et al. 2016). The major concern in this is its freshness due to certain post-milking microbial invasions that cause sourness and are capable of harboring pathogenic bacteria, which not only downgrades the taste and quality of the milk but also increases the chances of foodborne diseases if consumed. Therefore, in the milk industry as well as in home kitchens, it is boiled to remove unwanted microbes, which is technically known as pasteurization.

One of the confirmatory tests to evaluate the accuracy of pasteurization is the detection of contained alkaline phosphatase (ALP). Various tests worldwide have been developed for ALP detection based on advanced instrumentation and they often require multiple steps (Rankin et al. 2010), which cannot be utilized on-site with point-of-collection analyses. Hence, there was a high demand to develop a miniaturized bioanalytical system that can be operated in such points for ALP determination.

To address the issue, a duo team comprising of Mr. Kuldeep Mahato, a Ph.D. student, and his supervisor Prof. Pranjal Chandra from the Department of Biosciences and Bioengineering, Indian Institute of Technology Guwahati, Assam, India, has developed an immunobiosensor for naked-eye ALP determination in a miniaturized setting. ALP in this study was considered as the biomarker for the milk quality due to its denaturation point close to the destruction point of most of the pathogenic microbial forms present in the milk. The biosensor was developed on laboratory paper disc waste obtained from paper punch machines. The biosensor probe was developed utilizing facile chemical modification steps followed by immobilization of bioreceptors selective for ALP. The biosensor operates in a self-reporting mode, i.e. it does not require any extra labeling or tagging to generate the measurable signal.

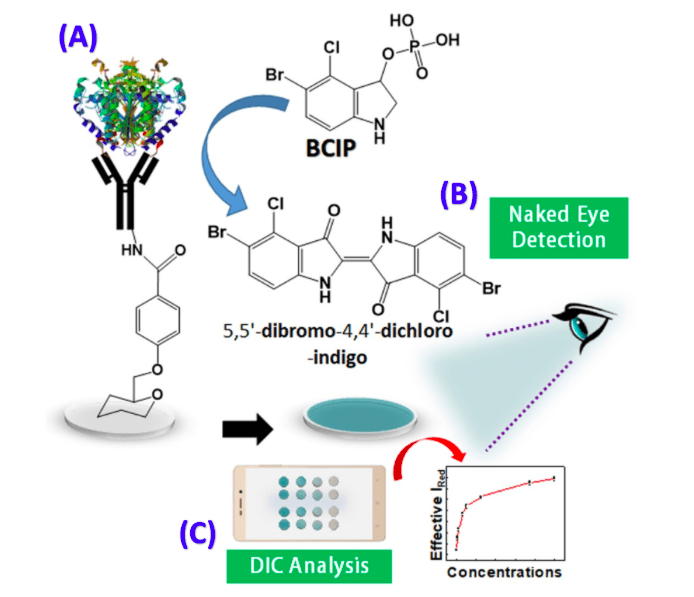

Figure 1 illustrates the biosensor configuration, sensing principle, and developed prototype. In addition to these, the biosensor is easy to handle, deliverable in the point of collections/distributions, and efficient enough to discriminate pasteurized milk from raw in just a few minutes.

The biosensor has shown excellent analytical performance where the estimation of ALP in the detection range of 10-1000 U/mL and the limit of detection of 0.87U/mL, covering the range of normally found ALP concentrations in milk in merely 13 minutes. It has also shown high selectivity towards ALP molecules, which makes it accurate and efficient even in the presence of various coexisting molecules. The developed biosensor is capable of discriminating the raw from the pasteurized milk, as in the former case, the ALP level falls in the range of the dynamic range of the biosensor, whilst in the latter case, the level is quite low and gives no detection.

Figure 1: (A) ALP captured biosensor probe and the sensing principle, (B) naked eye quantitative determination where the visual color appearance signifies the presence of ALP in the detection range, (C) The appeared color is captured using a smartphone camera and, thereby, the quantitative determination of ALP is obtained by digital image colorimetry. Image courtesy Pranjal Chandra.

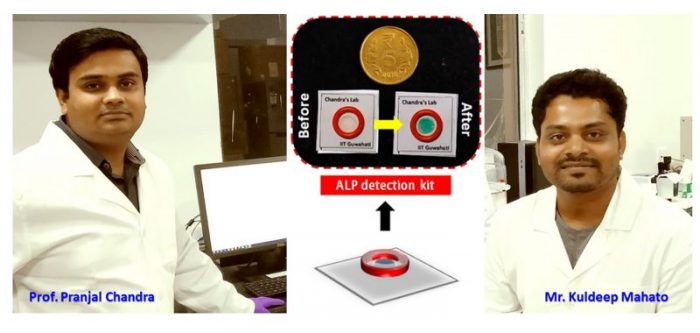

Based on the developed sensing mechanism, a miniaturized prototype has been developed for disposable onsite assessment determination of ALP in milk. This prototype is very simple to fabricate which uses the biodegradable substrate polymer for mechanical supports and paper-based detection zone, may attract the wide commercial attention. After the assembly of different parts, it becomes more handy with merely the dimension of 20.0 mm (L) x 20.0 mm (W) x 2.15 mm (H), which can be carried even in pocket wallets.

The team is working to improvise the analytical performance of ALP determination kit by incorporating other signal amplification strategies, which will consequently enhance the capability of giving better estimation in the future. The cost of the present prototype is estimated as not more than $1.5 in the laboratory scale, however, the authors anticipate that per-unit costs could decrease significantly in commercial-level mass production. Apart from this ALP biosensing, the research group is developing numerous prototypes for the determination of various other biomarkers of food safety and clinical importance.

In picture: Prof. Pranjal Chandra, developed miniaturized ALP kit; before and after sensing, and Mr. Kuldeep Mahato (left to right). Image courtesy Pranjal Chandra.

These findings are described in the article entitled Paper-based miniaturized immunosensor for naked eye ALP detection based on digital image colorimetry integrated with smartphone, recently published in the journal Biosensors and Bioelectronics. This work was conducted by Kuldeep Mahato and Pranjal Chandra from the Indian Institute of Technology Guwahati.

References:

- Coimbra DR, Selia J, Teixeira JA (2016) Engineering Aspects Of Milk And Dairy Products. CRC Press, ,

- Rankin SA, Christiansen A, Lee W, Banavara DS, Lopez-Hernandez A (2010) The application of alkaline phosphatase assays for the validation of milk product pasteurization. Journal of Dairy Science 93 (12):5538-5551. doi:10.3168/jds.2010-3400