Porous carbon materials (PCMs) hold great scientific and technological importance due to their ability to allow gases and liquids to penetrate their entire bulk.(1) They have been long regarded as key components for building up sustainable and clean energy technologies such as fuel cells, rechargeable batteries, supercapacitors, etc.(2) Especially, PCMs with open pores (including mesopores, macropores, and larger-sized pores) are more attractive in the abovementioned fields because open pores are able to provide fast communication between bulk medium and inner interfaces of PCMs.(3)

Despite their abundant resources and low costs, the synthetic strategies for PCMs have been mostly founded based on condensation of organic matters that are functionalized with H-, O-, N-, or S-moieties, followed by activation steps.(4) However, the energy for activating these bonds are usually very high, leaving some tough issues such as high-energy in demand, a large quantity of hazardous gas byproducts emitted, and hard control on structure and porosity.(4) Mostly, in order to introduce controllable meso-/macro-pores, solid or liquid templates with narrow size distributions are required.

To meet these ends, we have developed a novel strategy that enables fast fabrication of carbon materials under mild conditions. For instance, carbonaceous materials can be obtained in 60 seconds via dehalogenation of polyvinyl dichloride (PVDC) by KOH at room temperature, no hazardous byproduct was formed.(5) Meanwhile, following studies revealed that the dehalogenation strategy is applicable for the tunable synthesis of carbon materials with largely varied dopant types (N, S, P, O, or their combinations)(6-8), morphologies (sheet, crump, foam, etc) (5, 9, 10), and most importantly, widely tuned porosity(11, 12).

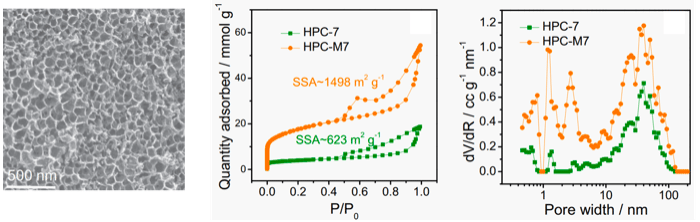

In this work, hierarchically porous carbon (HPC) materials with well-defined meso-/macro-pores are obtained via the dehalogenation reaction of polyvinyl difluoride (PVDF) by NaNH2. The mechanism of carbon formation is described by Eq. (1), accordingly, two important byproducts of NaF and NH3 are formed, which are applicable for in situ templating and bubbling intermediate carbon structure for meso-/macro-pores. Meanwhile, the intentionally left NaNH2 can further activate carbon for abundant microporosity (Eq. (2)). Electron microscopy studies and Brunauer–Emmett–Teller (BET) measurements confirmed that the structures of HPC samples contain multiple-scale pores assembled in a hierarchical pattern, and most of their volumes are contributed by mesopores, as displayed in Figure 1.

We managed to synthesize two types of HPC materials, the synthesis of HPC-7 followed the protocol mentioned above, the other one: HPC-M7 with much larger macropores was obtained by adding decomposable and vaporable component (melamine) before the dehalogenation reaction initiated. This specific finding relating secondary vaporable component may enable powerful tuning on pore types and their ratios of porous carbon materials.

Figure 1. Electron microscopy and BET characterizations on HPC materials. (Used with permission from Guoxin Zhang)

Improving specific energy of supercapacitors (SCs) at high power has been intensively investigated as a hot and challengeable topic. As for demonstration, HPC-M7 with abundant well-defined open pores as well as micropores was fabricated into aqueous symmetric supercapacitors (ASSCs). Electrochemical measurements revealed that HPC-M7 achieved an ultrahigh specific energy of 19 Wh kg-1 at the specific power of ~1 kW kg-1. Remarkably, at the ultrahigh power of 14 kW kg-1, the HPC-M7-ASSCs still delivered a very high specific energy of 17 Wh kg-1, meaning that the HPC-M7-ASSCs can be charged or discharged within 4 s.

These findings are described in the article entitled Fabricating Hierarchically Porous Carbon with Well-Defined Open Pores via Polymer Dehalogenation for High-Performance Supercapacitor recently published in the journal Applied Surface Science. This work was conducted by Mei Guo, Yu Li, Kewen Du, Chaochao Qiu, Gang Dou, and Guoxin Zhang from Shandong University of Science and Technology.