Published by Nesrin Ozalp and Hamed Abedini Najafabadi

Mechanical and Industrial Engineering Department, University of Minnesota Duluth, 55812, Duluth, MN; School of Chemical Engineering, Iran University of Science and Technology, Tehran, Iran

These findings are described in the article entitled An advanced modeling and experimental study to improve temperature uniformity of a solar receiver, recently published in the journal Energy (Energy 165, Part B (2018) 984-998). This work was conducted by Hamed Abedini Najafabadi from the Iran University of Science and Technology and Nesrin Ozalp from the University of Minnesota Duluth.

Capturing concentrated solar energy to produce fuels and commodities via a solar thermochemical process is an attractive and fast-emerging research area with significant potential to reduce greenhouse gases. The main component of this process is a solar reactor which captures the concentrated solar radiation to convert a feedstock gas to either fuel and/or an industrial commodity. For example, cracking natural gas via solar energy into its components yields hydrogen fuel and carbon black as a valuable commodity.

Maintenance of uniform temperature distribution and avoidance of hot spots in solar reactors is a challenge due to the point focusing of incoming solar radiation. Nonuniform temperature decreases the efficiency of the system and reduces system safety due to thermal shocks and deformation. Abedini Najafabadi and Ozalp (2018) pointed out these problems and presented a methodology that can be used as a design tool to enhance heat transfer inside reactors to achieve more uniform temperature distribution.

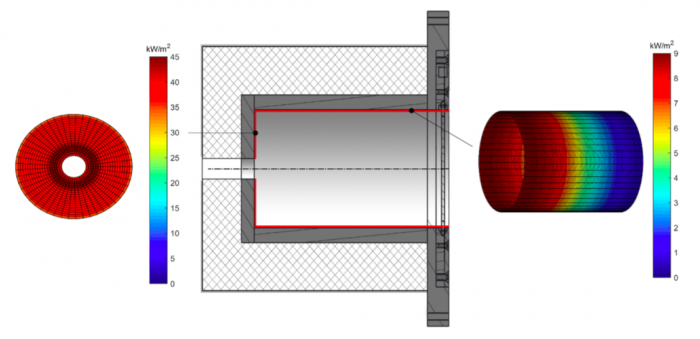

A cylindrical cavity reactor radiated by a 7kW solar simulator was used in the study of Abedini Najafabadi and Ozalp (2018). Experimental temperature measurements at different points of the inner cavity walls revealed a hot spot at the back plate of the solar reactor. Radiative heat transfer analysis confirmed that heat flux at the back plate was much higher than the other cavity walls (Figure 1).

Figure 1. Radiative heat flux distribution at the cylindrical cavity and the back plate. Image republished with permission from Elsevier from https://doi.org/10.1016/j.energy.2018.10.033.

As a measure of temperature uniformity in the solar reactor, a uniformity index was defined as the ratio of average reactor temperature to the difference between the highest and lowest temperature along the cavity cylinder. Several redesigns of the reactor were explored to improve the temperature distribution. Each design approach was evaluated via a detailed numerical model based on two-dimensional (2D) fluid flow dynamics and heat transfer simulations of the solar reactor. The model accuracy was validated by comparing the numerical results with experimentally measured temperatures at different points of the reactor.

The first approach was to swap the inlet and outlet gas ports. In the original geometry, the feedstock gas entered through three tangential inlets near the front flange and exited the cavity through a port on the back plate. By swapping the inlet and outlet ports, the gas carried the energy from hot surfaces to cold surfaces and promoted a more uniform temperature distribution. This modification increased the gas temperature by about 20%. However, it had an insignificant influence on reactor walls temperature due to the small contribution of internal convection to total heat transfer within the solar reactor.

The second design approach was to Increase the insulation thickness to reduce heat losses to the surrounding reactor. According to the simulation results, doubling the insulation layer thickness increased the temperature in the cavity cylinder by only 5%. Furthermore, increasing the insulation thickness did not improve the temperature uniformity in the cavity cylinder.

According to the energy analysis done by Abedini Najafabadi and Ozalp (2018), the front flange contributed significant heat loss to the surrounding due to its large surface area. Therefore, for the third redesign, the dimensions of the front flange were reduced. This modification increased the average temperature of the cavity cylinder by 7% and the uniformity index by 10%.

For the final modification, the length and radius of the reactor were changed while keeping the reactor volume constant. Decreasing the radius and increasing the length reactor increased the temperature uniformity index by 31%. Based on simulation results, reducing the front flange dimensions and decreasing the inner radius of the cavity reactor yielded the most uniform temperature distribution inside the solar reactor. By applying both of the modifications, the average temperature of the inner cavity cylinder walls was increased by 27% and the temperature uniformity index was increased by 58%.

An overview of the suggested design modifications to enhance the temperature distribution in the solar reactor are summarized in Figure 2. The methodology presented by Abedini Najafabadi and Ozalp (2018) can be used as a design tool to enhance heat transfer inside solar reactors. The reader can follow the steps in that paper to design their reactors or reactors with confidence and clearly understanding the physics behind the process to an extent not possible using commercial software.

Figure 2. Overview of solar reactor modifications to improve temperature distribution. Image republished with permission from Elsevier from https://doi.org/10.1016/j.energy.2018.10.033.

Reference:

- Abedini-Najafabadi, H., Ozalp, N. (2018). An advanced modeling and experimental study to improve temperature uniformity of a solar receiver. Energy, Vol. 165, p. 984-998.