“Economy of size is important; it allows economies of energy. Nature does it through evolution and adaptation – human ingenuity does it through elegance, short-cuts if you prefer,” offered Professor Ioan Stamatin, head of the 3Nano-SAE laboratory at the Faculty of Physics of the University of Bucharest in Romania. “Elegant design, enabled by advances in laser science and nanotechnology, can provide interesting solutions for the escalating issue of energy storage, in all its technological manifestations.”

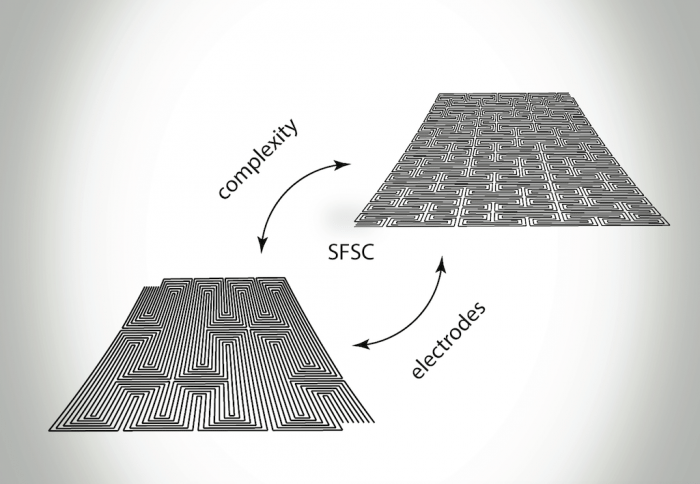

The Space-Filling Supercapacitor Carpet (SFSC) architecture allows for the symmetrical scaling up of planar supercapacitors beyond the size limits customary in microelectronics. It introduces a multiple nested electrode configuration based on pre-fractal designs; this allows supercapacitor devices to be incorporated into larger and more demanding applications. Developed as a doctoral and postdoctoral project, the patent-pending architecture is presented in the latest edition of the prestigious peer-reviewed Journal of Power Sources.

Credit: Thanos Tiliakos

Supercapacitors are rechargeable devices storing energy at the electrode-electrolyte interface, the electrochemical double-layer. With larger capacities than conventional capacitors, their charging-discharging rates climb higher than batteries. They are regarded as promising applications in electronics, communications, and transportation, displaying none of the hazards associated with batteries and offering environmental and operational safety alongside a near-infinite cycle life. Proposed applications include: uninterruptible power supplies (back-up protection against power disruption), load-levelers (back-up power for microelectronics), and auxiliary power sources for electric vehicles – provided their energy density can be amplified without sacrificing their power density.

Republished with permission from Elsevier from https://doi.org/10.1016/j.jpowsour.2018.02.061.

Dr. Thanos Tiliakos, the lead investigator of the project and inventor of the SFSC architecture, explained: “We started by considering alternative electrode blueprints. Space-filling curves are constructed by recursive algorithmic sequences, with successive iterations more closely approximating the space-filling limit. The overall length of a space-filling curve increases exponentially with each repetition of its root algorithm, with the highest iterations completely filling a surface.”

“Preceding fractal geometry by a century, space-filling curves are pre-fractal mathematical oddities. Their use in microelectronics is not a novel idea; in energy storage, they were proposed as early as in 1998; in communication electronics, they found implementation in antennas and resonators, phase shifters, multiband reflectors, and photonic crystals; recent developments also demonstrated their mechanical advantages in stretchable electronics. The key concept behind any application is to locate the proper geometry that satisfies its requirements with the least possible sacrifice – and there is always a price to be paid. In general, however, options are limited by the technological skill required to apply them.”

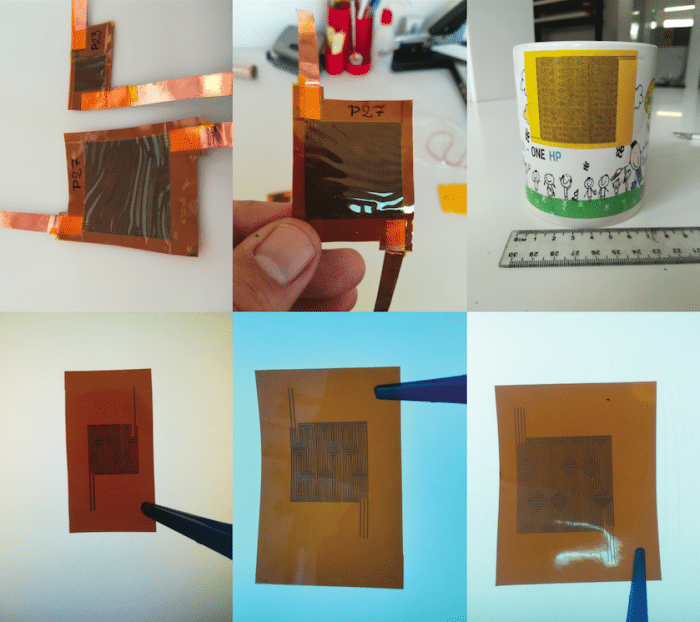

SFSCs are laser-printed via the LIG method of laser pyrolysis using commercial CO2 laser CNCs to photopyrolyze polyimide precursors into porous graphitic structures (graphene-based foams) of high electrical conductivity and double-layer capacitance. The LIG method, pioneered by the James Tour team of Rice University in 2014, was further investigated in earlier works by the Romanian team and was adapted to accommodate high-resolution printing of intricate designs, such as space-filling curves. This allowed the implementation of specific geometries that offer unmatched advantages compared to past microelectronic adaptations. Based on ternary instead of binary interval mappings, such curves allow the main electrode to be fitted with multiple – instead of a single – complimentary electrodes. Apart from the exponentially increasing length per iteration of each electrode, the distributed capacitance effect allows for fine-tuning both overall capacitance and equivalent series resistance by the appropriate selection of curve iterations and total number of nested electrodes.

Other advantages of the architecture include specific and gravimetric capacitance values relative to the electrode material (above the range established by past LIG applications, and higher than the range established by other graphene-based flexible devices); flexibility across all dimensions for flexible substrates, adding stretchability when transferred to elastomeric substrates; alternative orientations and configurations due to isomorphism; and non-regenerative endurance, allowing the device to survive structural damage by dividing into independent functional subunits.

Dr. Tiliakos – now at the National Institute for Laser, Plasma and Radiation Physics – concluded: “When design and technology meet, the end results are fascinating. With our current prototypes reaching footprints of 800 cm2, we are pushing towards the 1 m2 milestone with the associated capacitance and energy performance boosts, considering other applications of the SFSC architecture as well. This is only the beginning.”

These findings are described in the article Space-Filling Supercapacitor Carpets: Highly Scalable Fractal Architecture for Energy Storage, recently published in the Journal of Power Sources. This work was conducted by A. Tiliakos, A.M.I. Trefilov, E. Tanasӑ, A. Balan, and I. Stamatin from the University of Bucharest.

Associated work:

- A. Tiliakos, A.M.I. Trefilov, E. Tanasӑ, A. Balan, I. Stamatin (2018). Space-Filling Supercapacitor Carpets: Highly Scalable Fractal Architecture for Energy Storage. Journal of Power Sources 384, 145-155. (https://linkinghub.elsevier.com/retrieve/pii/S0378775318301824)

- A. Tiliakos, “Form-factor optimization of energy storage devices”, Nano S&T-2017 – 7th Annual World Congress of Nano Science and Technology, 24-26 October 2017, Fukuoka, Japan

- A. Tiliakos, C. Ceaus, S.M. Iordache, E. Vasile, I. Stamatin (2016). Morphic Transitions of Nanocarbons via Laser Pyrolysis of Polyimide Films. Journal of Analytical and Applied Pyrolysis 121, 275-286. (https://doi.org/10.1016/j.jaap.2016.08.007)