The use of live attenuated vaccine gdhA derivative Pasteurella multocida B:2 that can be administered intranasally is an alternative way to protect cattle and buffaloes from hemorrhagic septicaemi disease and increase vaccination coverage. Despite its proven record, however, there has been limited success in the development of a commercial live attenuated vaccine that is associated with the difficulty in maintaining the stability during long-term storage and the possibility of temperature variations during shipment.

The live attenuated vaccine mutant P. multocida B:2 was reported to survive only up to a maximum of 2 months in its liquid form (Oslan, 2013). Therefore, an efficient formulation strategy, particularly as a solid vaccine formulation, must be established to maximize the survival rate and extend the shelf life besides improving the activity of bacterial cells of the live vaccine. Furthermore, solid vaccine formulations may also overcome the drawbacks of hypodermic needle-based syringe injection liquid and also will be made easier for shipment as compared to liquid injectable vaccines that generally occupy large cargo sizes (Saroja et al., 2011).

Freeze-drying is an established method to formulate solid form biological products and preserve microorganisms in the most stable state by removing cellular fluid (Prakash et al., 2013). Nonetheless, freeze-drying might expose the bacterial cells to additional stressful processing step and hence reducing their viability. In general, freeze drying starts with a freezing step, followed by sublimation and desorption of the water from the product (Dietrich et al., 2016). A protective agent that is added to sample prior to freeze-drying may provide stability and protection against other inactivating mechanisms such as denaturation of sensitive proteins and decreased viability of many cell types (Carvalho et al., 2004).

Varying freezing-drying conditions during the freeze-drying of mutant P. multocida B:2 using a pilot-scale freeze-dryer (Epsilon 1-8D, Martin Christ, Germany) significantly affecting the cells survival rate. Longer durations of pre-freezing (-30°C, 1 bar) and main or primary drying (-30°C, 0.01 mbar) with a shorter final drying (0.001 mbar) steps for 24, 30 and 0.25 hours, respectively appeared to be a better strategy in preserving cell viability of P. multocida B:2 as compared to the other freeze-drying cycle with 10, 14 and 0.5 hours duration, respectively. An ample duration is required to fully convert the liquid product into ice crystal during the pre-freezing step to produce large contiguous ice crystals (Saclier et al., 2010). Besides, an adequate duration for primary drying is also important in ensuring a complete drying with low moisture content, which can further provide long-term storage stability of the powdered cell product obtained.

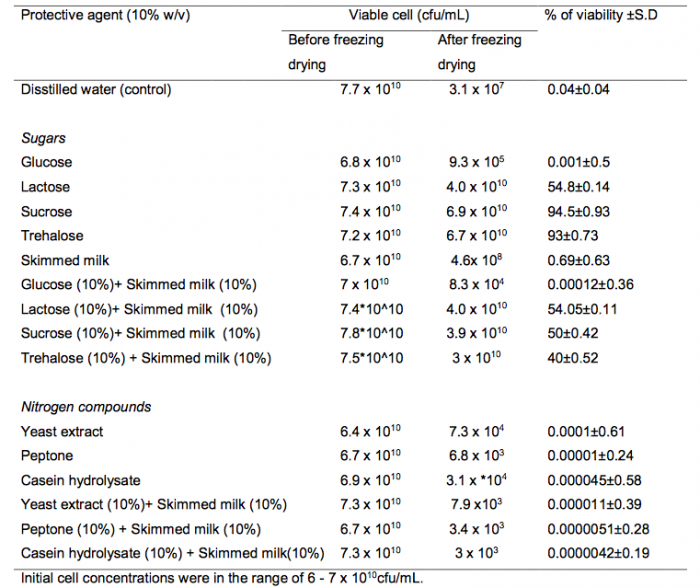

Table 1. The viability of mutant P.multocida B:2 cells formulated with 10% (w/v) of protective agents after freeze-drying process. Credit: Oslan et al., 2017, reproduced with permission from Elsevier.

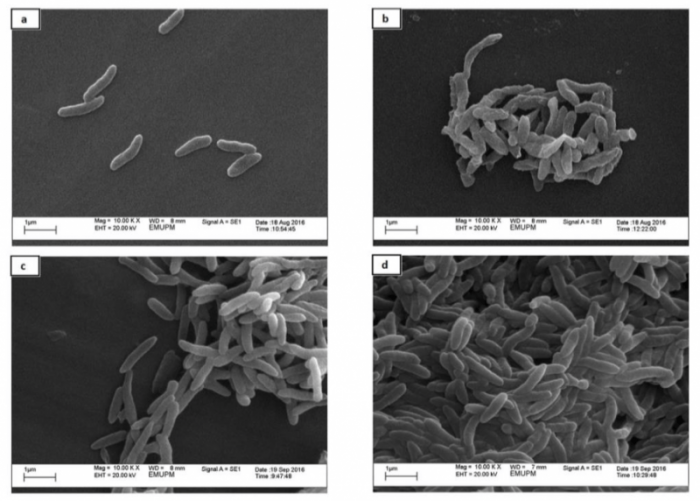

As tabulated in Table 1, among the fifteen protective agents tested, the highest percentages of viable cells were recorded with 10% (w/v) of sucrose and trehalose, resulting in 94.5% and 93%, respectively. Freeze dried mutant P. multocida B:2 cells in trehalose (Figure 1. (c)) or the mixture of trehalose and skimmed milk (Figure 1 (d)) displayed the cell wall and membrane in a good condition as compared to cells in distilled water (Figure 1(b)) that revealed a cell surface damage with shrinking and wrinkling. Lactose (10% w/v) used singly or in combination with 10% (w/v) of skimmed milk only managed to partially protect cells from the freeze-drying conditions with cell viability of 54%.

Figure 1. Scanning electron microscopy (SEM) images of freeze-dried mutant P. multocida B:2 cells in the presence and absence of protectants at magnification of ×10 000; (a) fresh cells without protectant, (b) cells in distilled water (control), (c) cells in trehalose (10% (w/v)), (d) cells in skimmed milk (10% (w/v)) and trehalose (10% (w/v)). Edited from Oslan et al., 2017.

In the meantime, the use of nitrogen compounds was inefficient in protecting mutant P. multocida B:2 cells at all tested concentrations. During storage study, freeze dried P. multocida B:2 in trehalose appeared to be the most stable with cell viability higher than 105 cfu/mL while storing at -30°C and 4 °C for up to 12 and 6 months, respectively. The cell viability that was maintained at higher than 105 cfu/mL during those storage periods is in the range of acceptable level (105 to 107 cfu/mL) for use in vaccination to control HS disease.

In general, the study revealed that besides protective agent formulation, the conditions applied during freeze drying technique also appeared to significantly influence the cells survivality. The conditions must hence be comprehensively verified and optimized in ensuring the vaccine product containing attenuated live cells of the highest quality and effectiveness.

These findings are described in the article entitled Improved stability of live attenuated vaccine gdhA derivative Pasteurella multocida B:2 by freeze drying method for use as animal vaccine, published in the journal Cryobiology. This work was conducted by Oslan S.N.H, Halim M., N Ramle N.A, Saad M.Z., Tan J.S, M.R., and Ariff A.B from the Universiti Putra Malaysia and Universiti Sains Malaysia.

References:

- Carvalho A.S., Silva J., Ho P., Teixeira P., Malcata F.X., Gibbs P. (2004). Relevant factors for the preparation of freeze-dried lactic acid bacteria. International Dairy Journal. 14:835–847.

- Dietrich S., Ana-Paula M.S. D., Isabella L.B. (2016). Optimization of a freeze-drying process for the biocontrol agent Pseudomonas spp. and its influence on viability, storability and efficacy. Biological Control, 94:74-81.

- Oslan S.N.H. (2013). In vivo survivality and optimization of parameters for biomass production of gdhA derivative of Pasteurella multocida B:2. Master of Science Thesis, Universiti Putra Malaysia.

- S.N.H, Halim M., N Ramle N.A, Saad M.Z., Tan J.S, M.R., Ariff A.B. (2017). Improved stability of live attenuated vaccine gdhA derivative Pasteurella multocida B:2 by freeze drying method for use as animal vaccine. Cryobiology. 79: 1-8.

- Prakash O., Nimonkar M., Shouche Y.S. (2013). Practice and prospects of microbial preservation. FEMS Microbiology Letters. 339:1-9.

- Saclier M., Peczalski R., Andrieu J. (2010). Effect of ultrasonically induced nucleation on ice crystals’ size and shape during freezing in vials. Chemical Engineering Science. 65:3064–3071.

- Saroja C.H., Lakshmi P.K., Bhaskaran S. (2011). Recent trends in vaccine delivery systems: A review. International Journal of Pharmaceutical Investigation. 1(2):64-74.