Providing sustainable alternatives to conventional concrete is becoming a global imperative, considering its significant footprints and versatile applications. Each year, every person on earth consumes about 1 ton of concrete.

For a small town with 53,000 people, this translates to an energy consumption of 660 average U.S. households and 3,710 tons of annual CO2 emissions. A cementitious binder made from coal fly ash presents a great business opportunity and contributes to environment and resource conservation, by diverting such industrial byproduct from waste stream into value-added applications.

Imagine a durable concrete with coal fly ash as the only binder and no need for cement or any heat treatment. This has long been considered impossible until demonstrated by a WSU group in a recent patent application. The key innovation is the use of graphene oxide (GO) at 0.02% by weight of Class C fly ash to catalyze its hydration and form calcium-aluminate-silicate-hydrate (C-A-S-H) gel at ambient temperature. This presents a great contrast to many advances made in the use of alternative cementitious binders to partially replace cement, and thus highlight a bolder approach to “greening” the cement and concrete industries.

In the context of diverting fly ash from the hazardous waste stream and reducing CO2 emissions, the alkali-activated fly ash geopolymer is being considered as one of the main treatments to solidify fly ash and as a sustainable construction material. Fly ash is a byproduct of coal combustion primarily from coal-fired power plants, captured at the top of boilers. U.S. fly ash production increased from 40.4 million tons in 1974 to 53.4 million tons in 2013, and 23.3 million tons (43%) of fly ash were used beneficially in 2013 [2]. The forecast value for U.S. fly ash production in 2033 will be 54.6 million tons and 35.7 million tons for utilization [3].

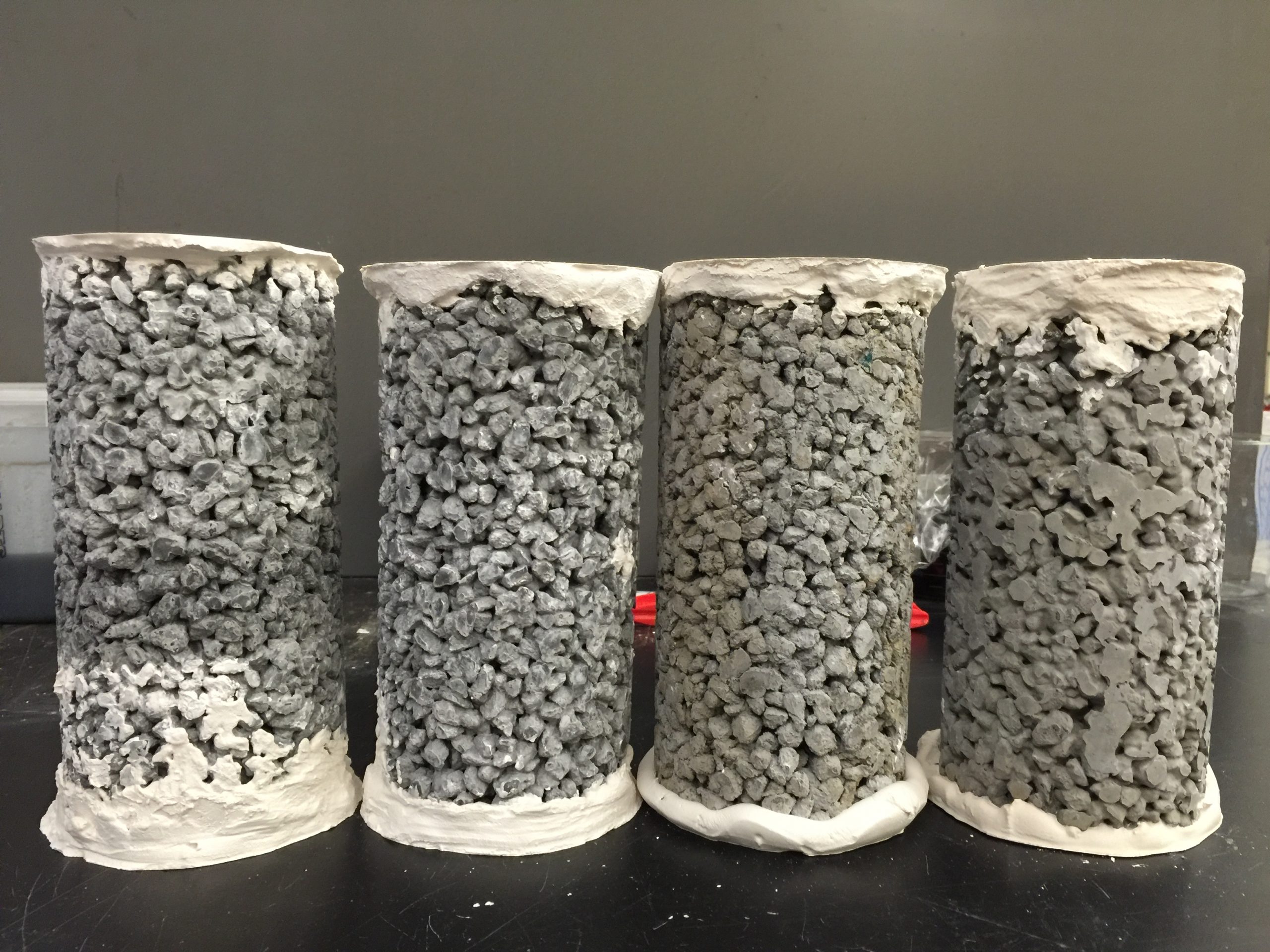

Credit: Xianming Shi

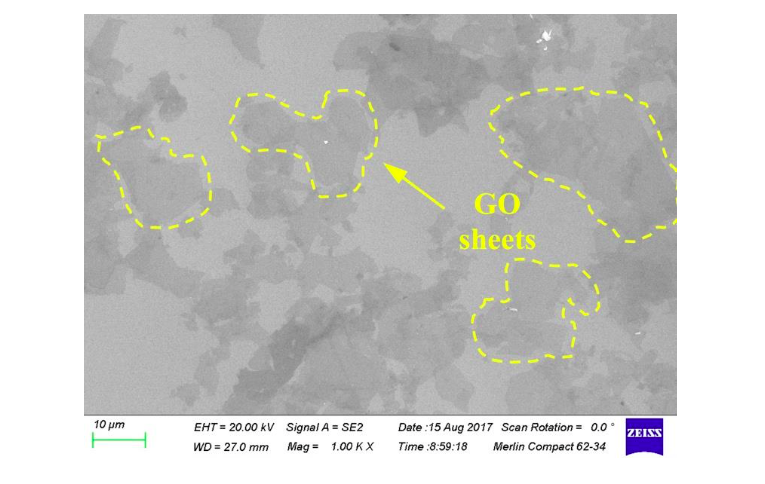

In order to improve the solidification of fly ash as construction material, graphene oxide (GO, a graphite-sourced nano-material) was employed in this work. Recent years have seen a growth in innovative research on the application of GO in engineering materials. GO (Fig.1) shows great potential as a concrete admixture because it is a two-dimensional carbon sheet with an aspect ratio up to 30,000 or higher [4]. It features a Young’s modulus of ~0.3 TPa and an intrinsic strength of ~112 GPa and is highly hydrophilic [5,6]. Different from graphene, GO is hydrophilic and more compatible with water, facilitating its dispersion in fresh concrete.

Fig. 1. Scanning electron microscope image of GO nanosheets.

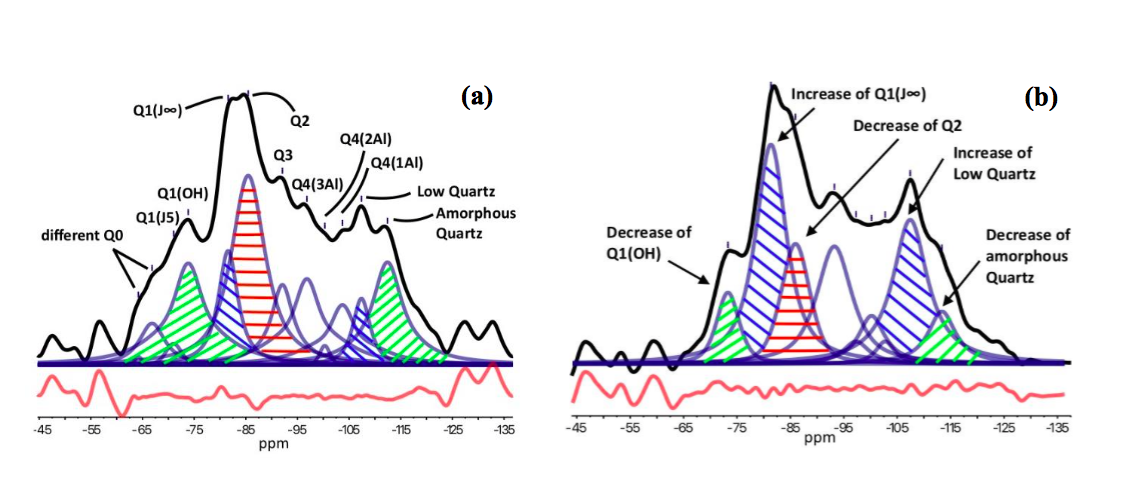

In the work by WSU’s Laboratory for Advanced & Sustainable Cementitious Materials (ASCM), the hydration precursors, morphology, elemental composition, mineralogy, and chemical structure and ordering of GO-modified fly ash geopolymer were investigated by means of Raman spectroscopy, SEM/BSE, EMPA, XRD/TGA, and 29Si/27Al MAS-NMR, respectively, to unravel the role of GO. The experimental results suggested that GO regulated the different elemental mole ratios to facilitate the formation of fly ash hydrates with improved mechanical strength, as GO showed the ability to selectively affect the distribution of different hydration precursors: (1) the electronegative GO sheet attracts cationic ions (Ca2+, Na+, K+, and Mg2+) and repels Al(OH)4 ̄tetrahedra and other electronegative ions; (2) the effect of GO on the Si-distribution was relatively weak because Si existed as both neutral Si(OH)4 units and SiO(OH)3 ̄, SiO2(OH)22 ̄ anions. The NMR study showed that GO also promoted the formation of low quartz and jennite-like hydrates (Fig. 2). Overall, the 0.02% GO can notably improve mechanical strength and appearance of fly ash geopolymer.

Fig. 2. 29Si MAS NMR Spectra at 56-day for (a) fly ash paste; (b) fly ash + GO paste

This work is significant as it shows that recent development of nano-size materials has given us the powerful tool to understand the world of molecules and atoms in the fly ash or cement hydration, which presents an opportunity to engineer concrete at molecular-level. Civil engineers have been mainly focusing on manipulating materials at meso- and macro-levels. For the sustainable advancement of the construction industry, we need to enable research across all scales (nano, micro, meso, and macro) and utilize this “bottom-up” capability of nanomaterial.

These findings are described in the article entitled, Influence of graphene oxide in a chemically activated fly ash, recently published in the journal Fuel. This work was conducted by Gang Xu and Xianming Shi from Washington State University, USA and Jing Zhong from the Harbin Institute of Technology, China. The technology reported in this work has been protected by a U.S. patent application and the fly ash pervious concrete slabs have been demonstrated on the WSU Pullman campus.

References:

- Yao ZT, Ji XS, Sarker PK, Tang JH, Ge LQ, Xia MS, et al. A comprehensive review on the applications of coal fly ash. Earth-Sci Rev 2015;141:105–21. doi:10.1016/j.earscirev.2014.11.016.

- ACAA. Coal Combustion Product (CCP) Production and Use, 2013. Farmington Hills, MI: American Coal Ash Association 2000; 2013.

- ACAA. Key Findings 2015, Coal Combustion Products Utilization, U.S. Historical Perspective and Forecast. American Coal Ash Association (ACAA); 2015.

- Tung VC, Allen MJ, Yang Y, Kaner RB. High-throughput solution processing of large-scale graphene. Nat Nanotechnol 2009;4:25–9. doi:10.1038/nnano.2008.329.

- Zandiatashbar A, Lee G-H, An SJ, Lee S, Mathew N, Terrones M, et al. Effect of defects on the intrinsic strength and stiffness of graphene. Nat Commun 2014;5. doi:10.1038/ncomms4186.

- Lee C, Wei X, Kysar JW, Hone J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008;321:385–8. doi:10.1126/science.1157996.