Spacecraft travel at high speeds and have to “brake” before landing onto a planet. When the planet has an atmosphere, aerodynamic drag can be utilized to dissipate the kinetic energy. This process is called atmospheric entry, which requires an aerodynamic decelerator/heat shield that generates sufficient drag, tolerates high temperature, and prevents excessive heat from entering the vehicle.

With the spacecraft getting larger and heavier for future space missions, such as human missions to Mars, the required heat shield size will become larger than the diameter of the largest existing rocket. Therefore, a deployable heat shield that can deploy from a small volume, like a balloon or an umbrella, is needed.

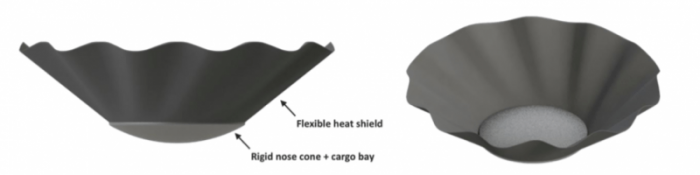

While the industry, including NASA and ESA, are exploring balloon-like inflatable structures and umbrella-like deployable mechanisms, researchers from the University of Manchester, UK, recently proposed a new approach, which utilizes a flexible heat shield shaped like a spiral skirt. It spins up like a sycamore seed during flight, deploys under centrifugal force, and regulates its own deployment. Its unique operating principle allows it to be lightweight, concise, and robust. This design not only responds to the demand for heavy Mars landers but may also enable new applications such as recoverable CubeSats for low-cost in-orbit scientific experiments, nano-probe swarm for planetary explorations, and hypersonic decelerators for recoverable rocket upper stage/components.

Credit: Rui Wu

Centrifugal deployment enables large but lightweight structures. To start from the first principle, elastic force is commonly used to deploy and support structures (e.g. balloons and umbrellas), but under certain scenarios, inertial force, such as centrifugal force, could yield better results.

According to a very basic analysis reported in the paper, in order to maintain the load-bearing capacity, the mass of an elastically supported structure has to increase exponentially when the structure is scaled up. On the other hand, the mass of a centrifugally supported structure tends to increase at a slower rate, and therefore could be large and relatively lightweight at the same time. An example is the helicopter rotor, which deflects even under its own weight when static but supports the whole aircraft once rotating at high speed.

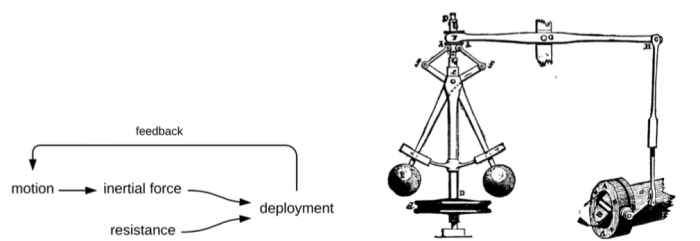

Besides centrifugal deployment, the interesting aspect of the proposed design is that it enables passive close loop control of the structural shape. The heat shield is based on a flexible fabric stitched-up along a spiral origami pattern, which generates an aerodynamic roll-torque to spin up the vehicle (autorotation). The centrifugal force thereby deploys and flattens the flexible shield, and with the flattening of the shield’s shape, the spinning motion will slow down. Finally, it will reach equilibrium at a certain extent of deployment, while this extent is determined by the ratio between atmospheric density and the shield’s areal density. Thanks to this principle, the heat shield naturally achieves near-full deployment at high altitude (i.e. at low air density), which means a stable aerodynamic profile and high drag coefficient is maintained throughout the critical flight regime.

Credit: Rui Wu (left) and Wikipedia (right)

This new design approach may bring various benefits to future entry systems. The fully-passive self-regulated operation allows the system to be concise and robust. The utilization of inertial force rather than elastic force allows large but lightweight designs. Since elastic rigidity is not needed, the shield can be made of very flexible materials such as ceramic fabrics that can be easily folded up for stowage while having a superior strength-to-mass ratio and temperature tolerance. Since inertial force can be generated as far as the heat shield has mass, it is less sensitive to temperature variation and has less thermal protection issues.

All these findings may be generalized by one sentence: Self-regulating passive centrifugal deployment can be achieved when the spinning motion is driven by an environmental torque that is coupled to the deployment condition. Its application is thereby not limited to entry systems. As an example, the researchers have published a paper on a metamaterial solar sail with self-regulated deployment, which benefits from being lightweight, concise, and robust. Interestingly, these passive self-regulating systems are somehow similar to the centrifugal governor invented by James Watt in 1788, which was used to stabilize the speed of a steam engine without active control input. By demonstrating the method to apply this old principle to heat shields and solar sails, researchers in Manchester open up new possibilities for future deployable space structures.

These findings are described in the articles entitled Flexible heat shield deployed by centrifugal force, and Heliogyro solar sail with self-regulated centrifugal deployment enabled by origami-inspired morphing reflector and Heliogyro solar sail with self-regulated centrifugal deployment enabled by origami-inspired morphing reflector, recently published in Acta Astronautica.

This work was conducted by Rui Wu, Peter C.E Roberts, Constantinos Soutis, and Carl Diver from the University of Manchester.